Hard candy production line equipment is divided into cast hard candy making machine and stamped hard candy production line, extruded hard candy production line, including cream-flavored sandwich hard candy production equipment, cast fruit-flavored gel hard candy processing machinery, stamped cool-flavored hard candy production machine and other candy production line equipment.

Jelly gummy candy production line customised small candy making machine

The hard candy making machine is a combination of equipment specially used to produce various types of hard candy, covering the entire process from raw material processing to finished product packaging.

Flow chart of hard candy production line

Raw material dissolving → Transporting → Storage → Dosing → Pre-heating → Micro-film cooking → Discharging → Mixing with flavor and color → Stick putting Depositing → Cooling → Demoulding → Conveying → Packing → Final product.

Technical parameters of lollipop making machine

| Model | YG-S150 | YG-S300 | YG-S450 | YG-S600 |

| Standard production volume | 150kg/h | 300kg/h | 450kg/h | 600kg/h |

| Candy weight | 2-6g | 2-6g | 2-6g | 2-6g |

| Pouring rate | 45-55n/min | 45-55n/min | 45-55n/min | 45-55n/min |

| Steam demand | 0.2m³/min 0.4-0.6Mpa | 0.2m³/min 0.4-0.6Mpa | 0.2m³/min 0.4-0.6Mpa | 0.2m³/min 0.4-0.6Mpa |

| Working environment requirements | Temperature: 20-25℃ Humidity: 55% | Temperature: 20-25℃ Humidity: 55% | Temperature: 20-25℃ Humidity: 55% | Temperature: 20-25℃ Humidity: 55% |

| Total power | 18kw/380V | 27kw/380V | 34kw/380V | 38kw/380V |

| Overall length | 15m | 17m | 17m | 20m |

| Overall weight | 3500kg | 4000kg | 4500kg | 5000kg |

Applications

This lollipop production line can produce kinds of hard candy, including nougat, toffee, lollipop, chocolate candy, milk candy, etc.

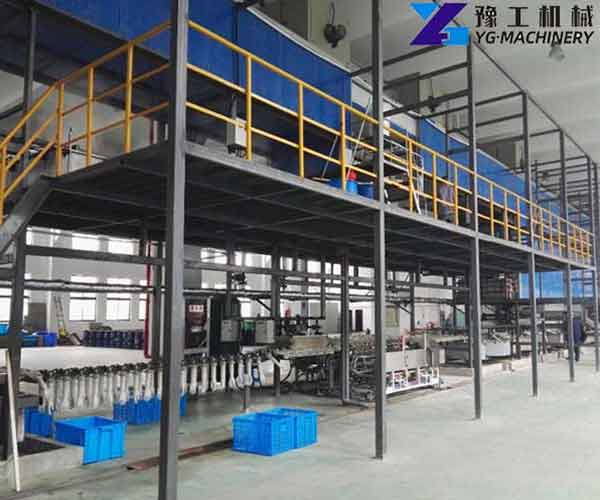

Key machines in this production line

Sugar dissolving system

Responsible for mixing sugar with other ingredients such as water and heating them to dissolve them. This process usually uses a vacuum sugar boiling pot to reduce the boiling temperature and reduce the risk of caramelization of the sugar solution.

Vacuum sugar boiling machine

This equipment can boil sugar solution under vacuum environment to ensure the quality and stability of the sugar solution, and is suitable for high-concentration and low-concentration syrup production.

Cooling system

It is used to quickly cool the hard candy after pouring to ensure its shape and taste. The cooling tunnel is designed for large-scale production to avoid deformation or adhesion of candy during the cooling process.

Pouring machine

Pouring the boiled sugar solution into the mold in a quantitative manner. Modern pouring machines are usually equipped with PLC control systems, which can accurately control the pouring speed and temperature to adapt to different types of hard candy production.

Packaging machine

The packaging machine can classify and package hard candies according to different flavors and colors.

Small hard candy making machine

Motor: servo motor

Material: 304 stainless steel

Power input: 110/220V AC/50-60HZ

Power output: 24V DC/MAX.1.5KW

Maximum temperature: 100 degrees

Applications: food, pills, candy, chocolate, etc.

Small hard candy making machine price

We are a If you are looking to invest the lollipop maker machine, please leave your messages below.