The concrete road cutting machine adopts a thickened frame and diamond saw blades. It is mainly used to cut the expansion joints of concrete roads. At the same time, it can cut and groove various specifications of concrete products, marble, and granite products. Construction machinery is necessary for road engineering. Click the message box below to get the concrete road cutting machine price or send an email to admin@ygroadmachine.com.

Parameter of Concrete Road Cutting Machine

| Model | YG-18 | ||

| Engine | Electric | Gasoline | Diesel |

| Power | 7.5kw | 13hp | 15HP |

| Blade diameter | 300-500mm | 400-500mm | 300-800mm |

| Max.Cutting depth | 180mm | 180mm | 180mm |

| Water tank capacity | 37L | 45L | 55L |

| Size | 1150*720*950mm | 1150*720*950mm | 1150*720*950mm |

| Weight | 225kg | 255kg | 255kg |

How Concrete Road Cutting Machine Works

The concrete road cutting machine adopts thickened frame and diamond saw blades. It is mainly used to cut the expansion joints of concrete roads. At the same time, it can cut and groove various types of concrete products, marble and granite products. Construction machinery necessary for road engineering; Click here you can check our concrete road cutting machine for sale.

Features of Road Slitting Machine for Sale:

- The rust-free water tank provides suitable water flow and volume for the blades—better cooling for the blade.

- The hinged front and lift-up blade guard makes the diamond blade replace conveniently.

- The height of the handle can be adjusted according to the comfort of the human body. The depth of the incision can be adjusted by turning the crank.

- The thickened frame makes the whole machine stable, resists warping and vibration; extends the service life of saws and blades.

- Simple structure, small size, and flexible operation.

The Purpose of Concrete Road Cutting Machine

- Provide professional cutting for municipal construction re-election, pavement maintenance construction, airport pavement cutting, communication engineering burying, floor, driveway, and other field operations;

- Replace different types of saw blades during use, which can effectively cut new and old concrete and asphalt roads, and can load water tanks for motorized cutting operations with water;

- Mainly used for cutting concrete, cement, floor, and stone pavements, cutting pavement shrinkage joints, or damaged pavements.

Features of Asphalt Road Cutting Machine :

- The machine cuts the anti-skid line automatically, the depth is adjustable, the anti-skid slot is straight, even, and beautiful.

- It adopts the famous brand spindle drive motor and the stepless variable speed motor, have strong power and superior performance.

- The rotary handle wheel has manual locking, which is easy to adjust and the depth of the engraving is consistent.

- Equipped with a large-capacity water tank, automatic spraying water to the saw blade during operation, so that the blade life is longer.

- The product has the advantages of convenient movement, flexible operation, and high efficiency.

Factors Affecting Road Cutting Machine:

- The cutting time has always been a factor to be considered in road construction, cutting crack is an important step in road maintenance. If the slitting time is not properly controlled, it will cause great damage to the next crack repair.

- The slitting time has a great relationship with the temperature. At the same time, the different temperatures, the slit will not be the same. Unreasonable depth of cut seam has a great influence on the construction of the road surfaces and also has a very important impact on the service life of the road, which leads to the mixture not fully utilizing its own potential and causing wasteful resources.

- Further, if the depth of the slit is too deep during the construction process, it causes a large amount of wear of the saw blade, and wastes a lot of manual labor, and can not achieve the desired effect. If the depth of the slit is too shallow, the panel cannot be broken at the corresponding position.

Working Principle of Road Engraving Machine:

The pavement engraving machine is composed of the main motor, walking part of traveling motor reducer gear, clutch, working lifting device, frame, cooling system, electric appliance, and other main components. The main motor drives the spindle to rotate at a high speed, the handwheel adjusts the depth of the engraving of the blade, and the walking switch controls the automatic walking.

Grooving Machine

In the road construction project, when the road surface is too smooth, the car traveling on the road is very prone to slipping during the operations such as turning and braking, so the road surface structure must be rough by milling, grooving, or others. Because the engraving can make the road surface have a smooth texture effect, it can achieve the purpose of increasing the friction of the road surface and preventing the slip, so the road cutting and the grooving machine has been widely used.

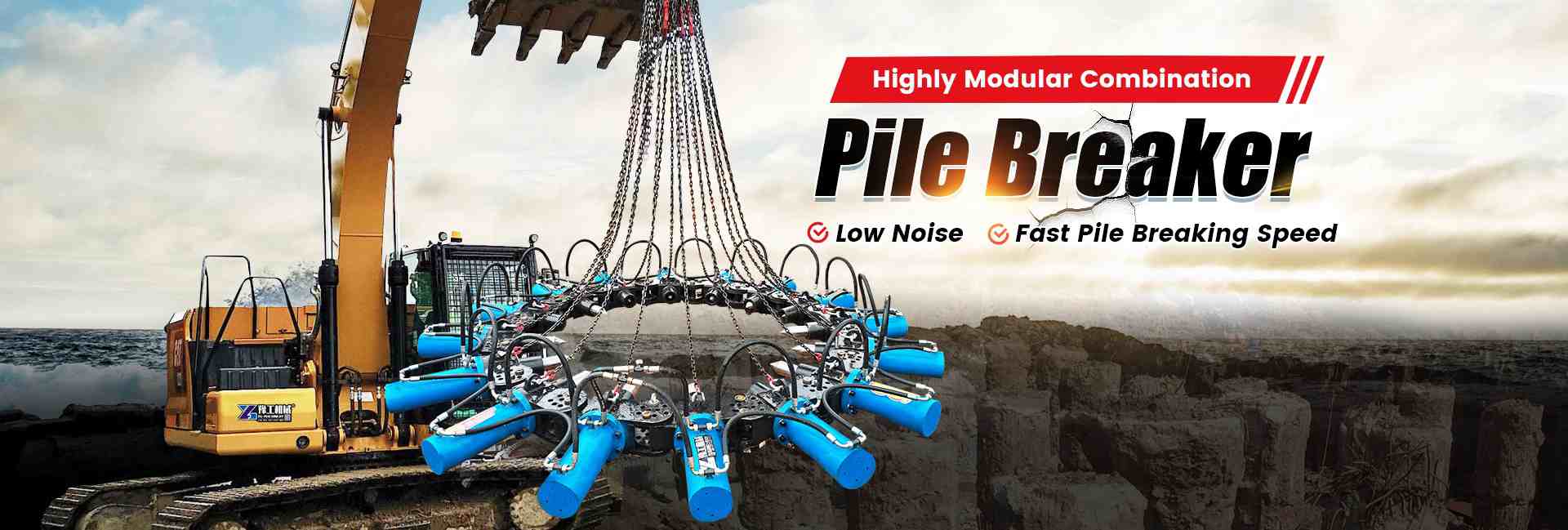

Concrete Road Cutting Machine Manufacturer – YG Machinery

YG machinery has been committed to the development of road machinery for more than 20 years. We have a professional technical team and are a professional machinery manufacturer. If you plan to build roads or are building bridges, tunnels, underground works, you can choose YG machinery. We have a mortar sprayer machine, mobile concrete pump, floor shot blaster, mini road roller, pile breaker machine, road marking machine, water drilling rig, anchor drilling machine, mist cannon, sand blaster machine, asphalt crack filler machine. Our professionals will help you solve all your doubts. and can provide high-quality products and the best service.