Infrared asphalt heater uses two easily obtainable fuels: liquefied petroleum gas and liquefied propane. After mixing liquefied gas and air in a certain ratio, it is burned on the surface of the metal fiber sintered felt, most of the heat generated by the combustion is converted into infrared light and heating asphalt pavement. Because infrared rays can penetrate the asphalt pavement, they can be heated to the deep layer of asphalt and softened in a short time.

The softened asphalt layer can be repaired after the processes of loosening, leveling, and compacting. Because there are no hot and cold joints of traditional maintenance methods, the repaired quality is better, the life is extended, and the maintenance cost is greatly reduced, and it is not affected by the season. YG Machinery also has more road repair equipment, such as crack sealing machine, asphalt crack sealing machine, asphalt crack filler machine, and so on. For more information, you can send an email to admin@ygroadmachine.com.

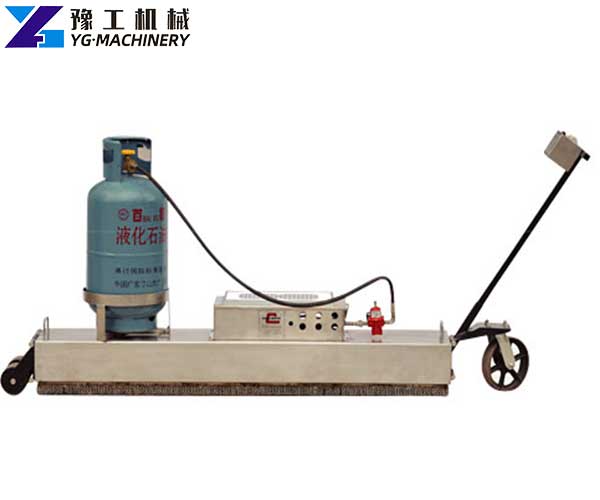

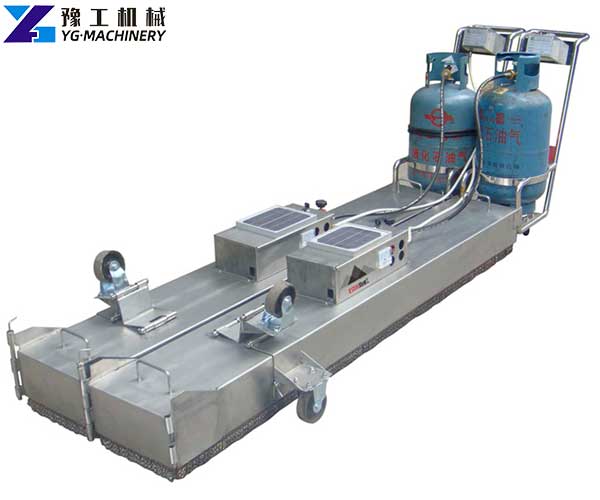

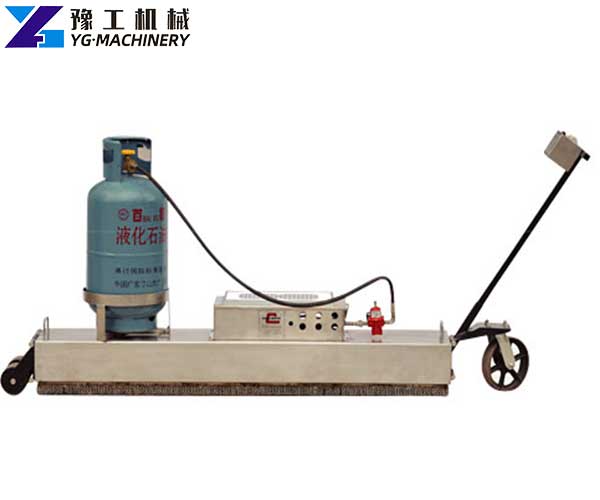

In order to meet the needs of different users, YG Machinery provides different types of infrared asphalt heaters for sale. There are many models for users: hand-push type is suitable for small area repair, trailer type is suitable for small or large area repair, and can be continued long time operation, the vehicle-mounted type is suitable for large-area highways and rapid repair. Please contact us for more information. YG infrared asphalt heater will be your ideal choice, please feel free to contact us to get the sales price of infrared asphalt repair equipment.

Uses of Infrared Asphalt Repair Equipment:

It is suitable for all diseases of the surface layer of asphalt pavement, such as pits, cracks, ruts, cracks, ridges, looseness, etc. At the same time, it can also be applied to the pavement excavation of municipal engineering, the treatment of railway junctions and culvert manhole covers, and making road shoulders. The processing of asphalt and concrete joint surface, the treatment of cold joints, the production of sidewalk pattern effects, etc. and can be used with the entire pavement of recycled pavement.

Parameter:

| Model | YG-1*8 | YG-4*4 | YG-S1600 |

| Dimensions | 2800*630*1200 | 1660*1160*1200 | 1660*1160*1200 |

| Weight | 90kg | 78kg | 500kg |

| Heating Area | 0.6㎡*2 | 1.35㎡ | 1.35㎡ |

| Operating Temperature | 140-170℃ | 140-170℃ | 140-170℃ |

| Heating Time | 5-15min | 5-15min | 5-15min |

Why Infrared Asphalt Repair and Patching is Very Effective?

- Low cost of use: the use of liquefied gas fuel, cheap and easy to obtain, a machine 2-3 people easy to operate.

- Electronic pulse ignition, easy and fast operation, overcomes the shortcomings of manual ignition, which is time-consuming, laborious, and difficult.

- Equipped with automatic flameout protection device, automatic temperature sensing, rapid heating at low heat, even long hours of work in a slightly harsh environment.

- Timing temperature control system, the control board centrally controls the heating time and the healing time is adjustable, the operation is simple, and it can be heated in whole or in sections.

- The operation effect is good: it is a real seamless repair, which can avoid the invasion of water, salt, oil, etc. into the repair area so that the service life of the repair area is longer than the surrounding area.

- High heating efficiency: the road surface softens to a thickness of 5-6cm within 5-8 minutes, and the surface does not scorch. Overcome the difficulties of low-temperature construction in winter.

- Environmental protection during construction: low emission, no pollution, and old asphalt materials can be recycled in the infrared repair process.

Precautions of Infrared Asphalt Repair Equipment:

- The stagnant water, loose asphalt, and dust in the area to be repaired must be thoroughly removed. Any debris will affect the repair effect.

- The position of the heating plate must be ensured. If the damaged area is larger than that of the hot plate, continuous repair can be used.

- The length of the pavement heating time should be properly controlled. If the heating is insufficient, the asphalt will be insufficiently softened and the repair effect will be poor, if the heating is too long, it will cause the asphalt to overheat.

- Once the heating plate is removed, level and loosen the area to be repaired immediately.

- Time and sunlight will partially oxidize the light oil in the asphalt. It is recommended to spray a little asphalt activator after loosening.

Advantages of Infrared Asphalt Heater Equipment:

- Simplify the repair process, the operation is simple and convenient, and the repair speed is fast.

- The repairing quality is good, and there is no weak seam, which can ensure that the repairing road surface and the original road surface are integrated.

- Asphalt material is regenerated on-site to save maintenance costs.

- Energy-saving and environmental protection, no waste.

- The impact on traffic is small, and both repairs are possible. to adapt to various seasons and weather, overcome the difficulties of winter construction.

Infrared Asphalt Heater Manufacturer-YG Machinery

In recent years, infrared asphalt repair equipment been used to repair the damaged areas of the road surface by heating and regeneration. This equipment can work around the clock, ensuring the timeliness of disease treatment; hotlinking of new and old roads to improve repair quality; a high degree of mechanization of equipment, reducing the labor level of workers. it is used in a wider range. As a road machinery manufacturer, we have many types of road machinery, such as road marking machines, crack sealing machines, small asphalt milling machines, mini road roller, floor shot blasters, asphalt recycling machine, etc.