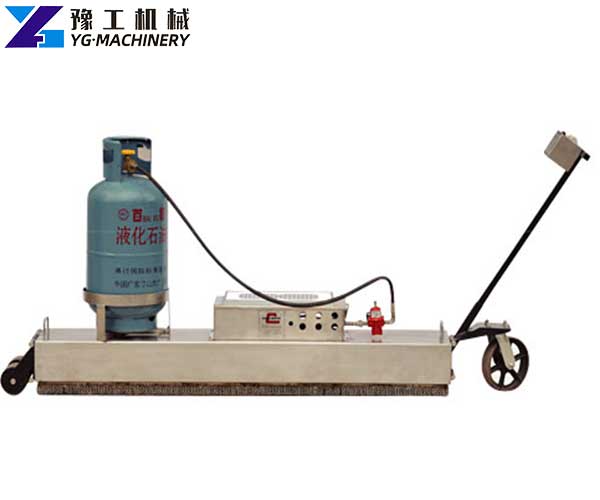

Road cracks are a common disease. How can we solve the problem? Asphalt crack sealer machine, blower, and road slot machine are the best choice for road crack maintenance. After grooving and cleaning the cracks, then the gun of asphalt grouting machine evenly fills the sealant into the grooves. So the asphalt filling machine can complete the repair work of road cracks.

YG-100 Asphalt crack sealer machine for sale

Asphalt crack sealer machine is also called asphalt crack filler machine, asphalt grouting machine. YG asphalt crack sealer machine can adapt to different situations and meet flexible and fast needs. If you need to fill the crack, please feel free to contact us.

Asphalt Crack Sealer Machine Parameter

- Model: YG-100

- Filling Capacity: 100L

- Heating Time: 30-40min

- Temperature Range: 0-200°C

- Discharge Capacity: 8 L/min

- Generator: Honda 2kw

- Walking Mode: Manual or Traction

- Burner: Riello 445T1 Diesel Engine

- Dimension: 2000*1000*1300mm

- Weight: 400kg

Applications of Asphalt Grouting Machine

An asphalt crack sealer machine is suitable for repairing the cracks on the pavement. It can effectively block the infiltration of water and prevent the further development of the disease. This method is one of the effective methods for the preventive maintenance of asphalt pavement. Through the prevention and treatment of pavement cracks, the life of the road becomes long, and the maintenance cost reduces to a certain extent. At present, asphalt crack sealer machines have been widely used in high-grade highways, urban roads, airport runways, and other projects.

Asphalt Crack Sealer Machine

| Model | YG-200 | YG-350 |

| Filling Capacity | 200L | 350l |

| Heating Time | 30-40min | 30-40min |

| Temperature Range | 0-200°C | 0-230°C |

| Discharge Capacity | 8L/min | 0-30 L/min |

| Generator | 2.8 KW | 5kw |

| Walking Mode | Manual or Traction | Trailer or Self |

| Length of Electric Heating Tube | 4-5 m | 6-7 m |

| Hot Melt Kettle | 200L | 350 L |

| Dimensions | 2400*1400*1700mm | 3500*1000*2000mm |

| Weight | 860kg | 1000kg |

Structures of Asphalt Crack Sealer Machine:

1. Burner

The burner adopts an Italian RIELLO 445T1 diesel burner. It has high combustion efficiency, safety, and environmental protection.

2. Automatic Constant Temperature Control

Adopts SLA-5000 intelligent digital temperature controller.

3. Electric Heating Tube

5 meters electric heating discharge hose.

4. Hot Melt Kettle

Unique oil jacket hot melt kettle design equips with a safety valve, heats faster and more uniform. Hot melt kettle is designed for anti-clogging.

5. Steam-electric Integration Technology

Steam-electric integration of hybrid power, and electric drive technology. It has the advantages of low emissions, low energy consumption, energy-saving, and environmental protection.

6. Intelligent Detection Technology

Advanced intelligent ignition, detection, and temperature control technology.

7. Thermal Cycle Heating System Design

The hot air double-circulation convection heating in the kettle, in addition, the metal sheet has high heat conduction efficiency, which makes the crack sealing machine more energy-saving and environmentally friendly. The heat-conducting oil jacket has higher energy storage, an obvious heat-conducting effect, and a stable constant temperature. A separation device is installed between the hot melt kettle, and it can speed up the melting speed and greatly improve work efficiency.

8. Efficient Discharge System

Efficient discharge system design, detachable built-in oil pump, no leakage. The temperature of the pump body is always the same as the filling glue, and there is no clogging phenomenon. A constant pressure protection device can effectively prevent the tube from scalding.

9. Low Center of Gravity Design

The low center of gravity design makes work safer and comfort and reduces labor intensity.

10. Stirring System

Electric high-torque stirring shortens the dissolving time by nearly half.

The Correct Operation of Asphalt Crack Sealer Machine

Preparatory Work

- Choose a smooth road, take good safety protection measures, lay the asphalt crack sealer machine on the flat floor, and lock the wheels. Open the fuel tank cap of the generator set and burner. Inject an appropriate amount of gasoline into the generator set, and inject the appropriate amount of diesel oil into the burner. Lock the fuel tank caps, and clean up the oil stains overflowing the fuel tank.

- Turn off all electrical switches in the electrical control box.

- Set the choke valve handle of the generator set to the choke position, the flameout switch to the OFF position, and the carburetor oil switch to the ON position.

Note: It is strictly forbidden to inject fuel oil when the hot melt kettle is at a high temperature, which may easily cause fire or explosion. Do not place flammable materials near running engines and hot melt kettles. If you are looking for an asphalt crack sealer machine for sale, please leave a message.

The steps of using an Asphalt Crack Sealer Machine for small pavement:

- First, use a pavement slotting machine to slot the cracks, and grasp the size of the slotting to ensure that the asphalt pavement joint glue and the pavement can be better combined.

- To ensure that the cracks of the slot are clean, use a road blower to clean the dust, debris, and surrounding debris in the cracks.

- Heat the asphalt pavement joint glue to a temperature between 185℃-195℃ to completely melt, and then perform the joint filling and sealing work.

- The pavement joint filling machine heats, stir, and melts the asphalt pavement joint filling glue, and then transports it out through the asphalt pump pipeline and pours it into the cleaned slot.

- The filling work should be carried out continuously, the grooves should be fully filled from bottom to top, and air bubbles should be avoided in the lower part of the filler.

- After the crack is poured, wait for the filling glue to fully solidify before releasing traffic.

Other Products

Henan YG Machinery is a machinery manufacturer integrating the manufacturing and sales of road machinery, construction machinery, steel machinery, drilling equipment, and other products. Our main products include: road marking machine, fog cannon dust suppression machine, crack sealing machine, mini road roller, pile breaker, concrete wet spraying machine, water well drilling rigs, etc… For more product details, you can add my WhatsApp +86 13598866720.