French fries are a portion of simple and ordinary snack food. It has already occupied a certain position in the current food market. It has also become a component of important foods in western countries, and its flavor and rich nutrition are more and more accepted and loved by people all over the world. Therefore, investment in potato food processing is a promising industry. French fries making machine is a piece of ideal processing equipment for the vegetable processing industry to make fresh vegetables and dehydrated vegetables, and it is also an ideal machine for the fast-food industry to process french fries.

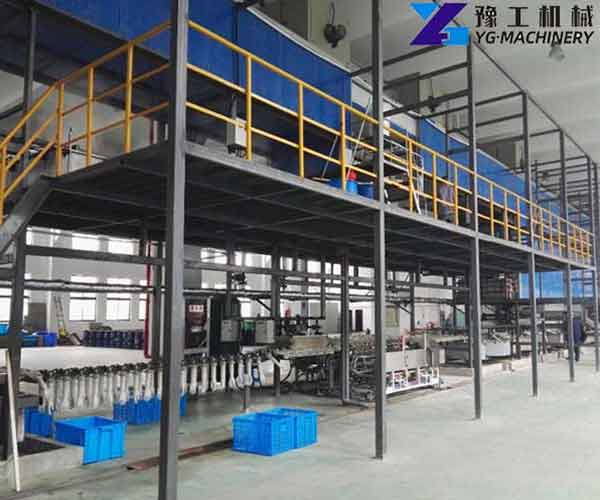

It has low one-time investment, low energy consumption, multiple functions, small size, high profit, convenient use, and maintenance, etc. High degree of automation, low labor intensity, french fries production line equipment, saving manpower, and high production efficiency. Please contact us for a free quote.

Classification of Fries Making Machine:

- The process flow of the automatic french fries making machine: increase the feed → wash and peel → select and trim → increase the feed → slice and cut → rinse → blanch and protect color → dehydration → frying → degreasing → seasoning → packaging

- Process flow of frozen french fries making machine: increase feeding→cleaning and peeling→selecting and trimming→increasing feeding→slicing and cutting→rinsing→blanching and protecting color→dehydrating→frying→deoiling→conveying→packing→quick freezing

Frozen French Fries Making Machine

Quick-frozen french fries are becoming more and more popular among people. The reason is that they are easy and fast to process at home. The most important thing is that they have good taste, fragrant and delicious. The quick-frozen french fries production line processes fresh potatoes through a series of processes, and the final product is quick-frozen french fries, which can be fried and used at any time when they are bought home. They are deeply loved by consumers.

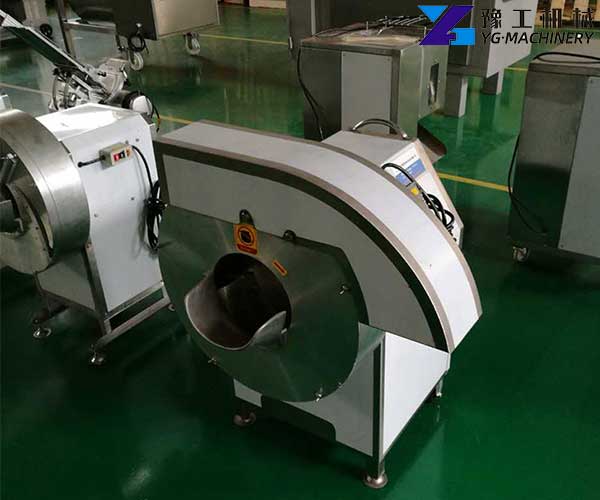

The cleaned and peeled fresh potatoes enter the cutting machine through the picking line. The size of the strips can be adjusted according to customer requirements. After the blanching line, the starch on the surface of the potato strips is removed while maintaining the color of the potato strips to prevent blackening. After blanching, the water on the surface of the potato strips can be effectively removed through the air drying line, and then enter the frying line. Quick-frozen french fries have a short frying time, and then are cooled by air-cooled oil, and then enter the quick-freezer and packaging machine.

Operation Process:

Lifting Machine: automatic lifting and feeding, convenient and efficient, saving manpower.

Washing and Peeling Machine: automatic potato washing and peeling, high efficiency, and energy-saving.

Picking Line: remove the pits of the potatoes to improve the quality.

Strip Cutting Machine: high-efficiency cutting, adjustable size.

Conveyor: Lift the potato strips to the blanching machine.

Blanching Machine: remove the starch on the surface of potato strips, inhibit the activity of active enzymes, and protect the color.

Vibrating Drainer: Remove the waste material that is too small and vibrate to remove excess water.

The Air-cooling Line to Remove Water: The air-cooling action removes the surface moisture of the fries and transports them to the fryer.

Fryer: Deep-fried and colored, and optimize the taste and taste.

Vibration Oil Drain Machine: Vibrate to remove excess oil.

The Air-cooled Line Degreasing and Cooling: blow off the excess oil on the surface, and fully cool the fries to enter the quick-freezer.

Quick-Freezer: Quick-frozen French fries are convenient for storage and transportation after packaging to optimize the taste.

Automatic Seasoning Machine: The drum-type seasoning machine is made of stainless steel, turned evenly, and sprinkled or sprayed to add seasonings. The seasoning is even and not fragile.

Packing Machine: according to the weight of the customer’s requirements, fully automatic packaging of quick-frozen French fries.

French Fries Making Machine Price

This production line is made of high-quality stainless steel with reasonable structure and exquisite workmanship. It can be equipped with front-end and back-end equipment according to the fried products to fully realize automatic production. It has the advantages of low one-time investment, low energy consumption, multiple functions, small size, high profit, and convenient use and maintenance.

In recent years, YG French fries making machines are selling well in many countries and regions at home and abroad. If you are looking for a reliable French fries production line manufacturer, we will be your ideal choice. Now, please feel free to leave a message. You will get a surprise prize for the french fries making machine.