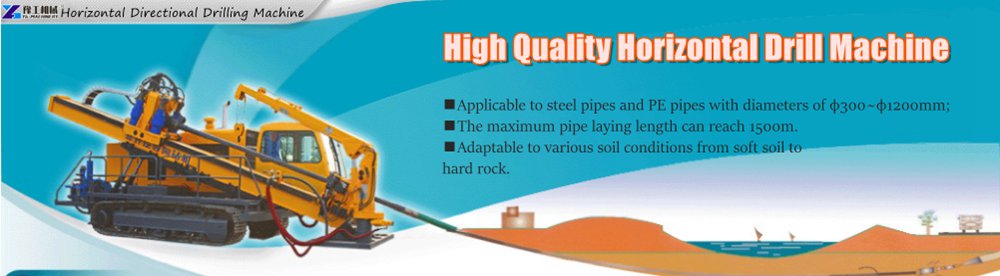

YG320C-LS Horizontal Directional Boring Equipment

Engine model: Cummins

Maximum pullback force: 700 KN

Maximum torque: 12600 N.m

Max. Drilling Length: 400 m

Main performance features

- The machine is equipped with Cummins engine with high efficiency, big power, low fuel consumption, low noise and strong ability in construction.

- It is equipped with technology used in the military industry (hydraulics). The Push & Pull and Rotation hydraulic system uses advanced series of parallel control technology and international first-class hydraulic components with high efficiency, low consumption and high stability.

- The directional boring equipment is equipped with rotary and push & pull pilot control, and the operation is more accurate.

- The rotation of the gearbox is driven by a high-torque American Eaton motor, which is stable in performance and achieves continuously variable speed. Push & pull uses an American Eaton motor and three-stage speed control.

- The transmission is strengthened compared to all competing models – It has a huge torque and a large tractive force.

- It is equipped with a first-class chassis. The running of the chassis is powered by a wire control, which is suitable for loading, unloading and moving.

- The cabin uses a man-machine construction method, which is convenient for operation and can greatly reduce the fatigue level of workers. The swivel cab is optional with air conditioning, a wide view and a comfortable seat.

- The machine is equipped with drill rods φ73×3000 mm or φ76×3000 mm or φ83×3000 mm, it has a medium field of operation, meeting the requirement of high efficiency of the structure in a small place.

- The electrical construction is of high quality with low failure rate, and easy to maintain.

- The HDD machine is beautiful and easy to repair, which fully shows the vision of “people-oriented” design.

- The design of the gun carriage is advanced and the work efficiency has been improved by 30%. It is far ahead of other manufacturers in the trenchless industry.

- Humanizing design: The mechanical arm can greatly improve work efficiency and reduce labor intensity. And clients can choose cabin (with air conditioner), automatic loading box, automatic anchor, automatic oiling machine, etc.

- Newly designed instrument panel, optional Mag9 color display, can record well Chart etc.

Directional boring machines working principle

A small-diameter pilot hole is drilled along the desired path using a rotating drill bit. The horizontal drilling machine uses guidance systems, including gyroscopic sensors and locating equipment, to control the drilling direction. After the pilot hole is created, the directional boring machine utilizes a reaming tool to enlarge the hole to the desired diameter.

Construction characteristics of horizontal directional drilling

- The construction of directional drill crossing will not hinder traffic, will not damage green spaces, vegetation and buildings, and will not affect the normal life and work order of residents.

- Modern crossing equipment has high crossing accuracy and is easy to adjust the laying direction and burial depth.

- The burial depth of urban pipe networks is generally less than three meters. When crossing rivers, the burial depth is generally 9-18 meters under the river bed.

- There will be no above-water or underwater operations, it will not affect river navigation, and it will not damage the dams and riverbed structures on both sides of the river.

- It is fast to enter and exit the site, and the construction site can be flexibly adjusted.

- Pre-expanding is to expand the hole back to the expected diameter step by step according to 1.3~1.5 times of the pipe diameter when the geological conditions and underground pipeline detection or survey are clear.

Our Services

We also provide Accessories

Drill Bits and Reamers

Various types and sizes of drill bits and reamers are available to match specific soil conditions and project requirements. They ensure efficient penetration and hole enlargement during the drilling process.

Explore Features

Locating Equipment

Specialized locating equipment, such as electronic trackers and sonde transmitters, helps operators precisely track the location of the drilling head and guide its path accurately.

Contact Sales

What can be used the directional boring equipment?

Directional boring equipment has been extensively used for the installation of utilities, such as fiber optic cables, gas pipelines, water lines, and electrical conduits, in urban areas and sensitive environments.