Congratulations! YG-30 Slipform curb machine exported to Indonesia. We look forward to seeing the YG-30 in action in Indonesia.

Have you ever wondered what a curb is and how it’s constructed? In this article, we will explore the concept of curbs, delve into the functionality of curb slipform machines, and provide all the essential information you need to understand this vital piece of construction equipment.

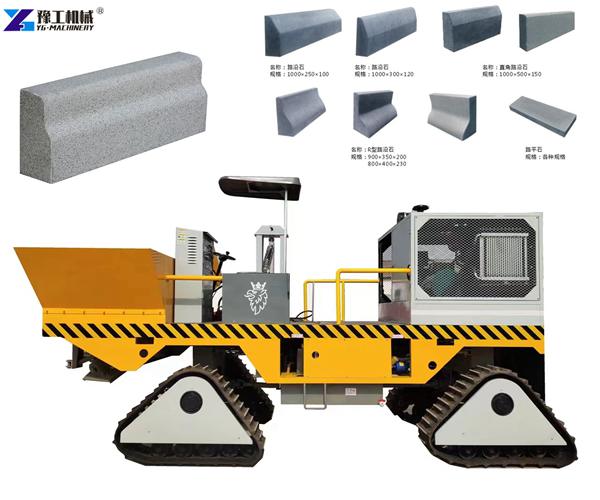

What is a slipform curb machine?

In terms of application, a slipform kerb machine is a machine for building shoulders, including highways, municipal roads and residential areas. What is a shoulder? A shoulder is also called a curb. It is a strip-shaped boundary stone on both sides of the road surface used to ensure the edge of the road surface is neat and distinguish the road surface. Some curb stones are in pieces, while the shoulder built by the curb slipform machine is formed in one go by continuous paving.

Technical Infomations of slipform kerb machine for sale

| Model | YG-30 Multifonctional Fully Automatic Curb & Gutter Machine |

| Size | 5200*2400*2800mm |

| Construction scope | Width ≤ 2000mm (road shoulder, gutter), height ≤ 600mm (kerb, curb stone) |

| Weight | About 8000kg |

| Engine | 65kw, 380v, 4-cylinder turbodiesel engine |

| Forming method | High frequency vibrator (Applicable to plastic concrete) Formed shoulders and gutter have higher strength |

| Attached vibration motor (Applicable to dry hard concrete) Curb stones can be paved, and the height of the curb stones is higher. | |

| Automatic leveling system | Leveling range ±40mm |

| Steering Type | Dual automatic steering system |

| Minimum turning radius | 6800mm |

| Paving and transition speed | 1m-10m/min |

| Hopper volume | 1m³ |

| Walking drive form | Full-time four-wheel drive |

Have questions about the features and capabilities of slipform curb machine? We’re here to help—just ask!

Application conditions of slipform curb machine

- Highway and municipal road construction: curbs, central isolation belts, crash barriers, slope protection and drainage ditches, etc.

- Railway construction: retaining walls, drainage ditches, etc.

- Agriculture and water conservancy construction: anti-seepage canals, slope protection and road hardening, etc.

Features of concrete curb and gutter machine

- Friendly and intuitive human-machine interface.

- This machine meets the requirements of high efficiency and environmental protection, with sufficient power surplus, and can cope with various harsh working conditions.

- Single crawler hydraulic drive, stable walking, good adhesion.

- Equipped with high-precision automatic leveling and automatic steering functions, it can accurately pave according to the specified elevation and line shape.

- Adopt built-in vibrating rod vibration to ensure that the concrete surface is smooth and the inside is dense after paving.

- Equipped with a complete set of high-pressure water washing equipment and various random tools, slipform curb machine is convenient for field work and maintenance of the machine.

- According to different construction requirements, a variety of molds can be selected for users under reasonable design parameters to improve the utilization rate of the paver.

Looking for information on how to choose the right curb slipform curb machine for your needs? Inquire with us today!

Curb and Gutter Machine Categories

Slipform curb machine is essential in modern concrete construction, allowing for continuous paving processes. There is 4 types based on their working principles: extrusion type, hammer type, vibration type, and another vibration type (likely referring to a variation in design or application).

Extrusion Type

In extrusion-type slipform machines, a mixture of concrete is continuously pushed into a forming mold by a screw propeller. This method generates significant extrusion force within the mixture, leading to the formation of curbstones with specific density, strength, and shape. The horizontal reaction force exerted by the mixture on the screw conveyor is transmitted to the machine’s frame and travel wheels, facilitating movement along the road surface.

Hammer Type

Hammer-type machines feature a hammer head device that performs a piston-like reciprocating motion. This action pushes the cement concrete into the forming mold at set intervals, effectively extruding the curbstone. The machine’s movement relies on the reaction force generated by the self-impacting hammer movement, making it distinct from other types.

Vibration Type

Vibration-type slipform machines incorporate a vibrating rod positioned in front of the forming mold. This rod aids in achieving the desired density of the cement concrete through vibration. The continuous motion of the machine is influenced by the mechanical systems within rather than external forces.

High-Frequency Vibration Type

Another variation of vibration-type machines employs a high-frequency, low-amplitude vibrator mounted on the mold itself. This setup enhances the density of the cement concrete while ensuring that the machine’s movement is stable and independent of reaction forces from the mixture. This design allows for smoother operation and better control over the paving process.

Conclusion

Curb slipform machines play a vital role in modern construction by streamlining the process of creating essential infrastructure components like curbs. Their ability to produce high-quality, uniform structures quickly makes them indispensable for contractors involved in large-scale paving projects.

Henan Yugong Machinery provides various machines for road construction. We provide road shot blasting machine, mini road roller, road cutting machine, etc. If you need to buy a Slipform Concrete Curb Machine, feel free to leave your messages below. Our sales manager will contact you as soon as possible.