How are made engine oil bottles? Maybe you heared about plastic bottle blowing machine. Does it can also make engine oil bottles? The answer is no. To produce the engine oil bottles, we need a machine called blow molding machine – engine oil bottle making machine.

What is a Blow moulding machine?

A blow moulding machine is also called bottle blowing machine or hollow molding machine. Blow moulding machine is a single-station process that starts with plastic pellets or powder and ends with a finished container or plastic hollow product that can be delivered for packaging. It is specialized in the production of various plastic bottles for washing and cosmetic packaging, oil bottles, medical plastic bottles and plastic barrels, etc., to meet user requirements for hollow products of different specifications from 0.1 to 30L.

Read also: Plastic injection moulding machine

3L 4L 5L Engine oil bottle making machine

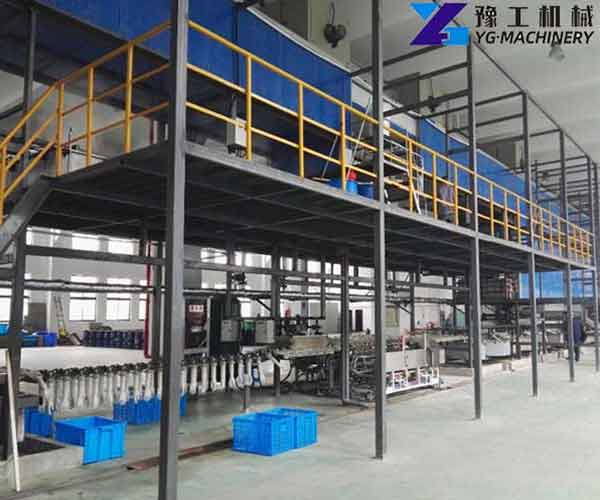

The large, medium and small blow molding equipment (Engine oil bottle making machine) we produce are suitable for the production of 0.01-5000 liters of plastic bottles, plastic pots, plastic barrels, plastic bags, plastic toys, plastic pallets, oversized plastic barrels and other hollow products.

A see-through marking line and an automatic labeling system can be added to clearly see the level of the liquid contained and improve the quality of the product.

| Model | YG-S2L | YG-S5L | YG-D5L | YG-D15L |

| Raw Material | PE PP PVC PA PET HDPE…. | |||

| Max.product capacity | 2L | 5L | 5L | 15L |

| Clamping force | 90KN | 90KN | 90KN | 110KN |

Check here what can be produced with this machine

Large industrial containers, tanks specifically designed to store liquid materials. For example: buckets, IBCs, rainwater tanks, double-ring buckets, trays, lids, air tanks, etc.

Why you should use YG Bottle Blowing Machine?

- Efficient and intelligent. The touch display can be used for parameter setting, modification, adjustment and monitoring. The engine oil bottle making machine operating parameters can be observed at any time, making it more intelligent and improving production efficiency.

- Strong professionalism. National high-tech enterprise, blow molding expert with more than 30 years. CE, SGS certification.

- Blow molding process. The product has beautiful color, shape, fine ingredients, uniform wall thickness, durability, strong pressure resistance, long service life, and saves costs.

- Customized design. YG has a mold production workshop that can customize product size specifications according to needs. Precision molds are used in conjunction with blow molding machines. We produce multi-layer (1-8 layers) blow molding machines.The one-stop blow molding solution allows you to get twice the result with half the effort!

Blow molding Machine VS Bottle Blowing Machine

Which is better, blow molding machine or bottle blowing machine? Both the machines are commonly used plastic production equipment. They are similar but have certain differences.

Working principe comparison

- Working principe of Blow molding machine

Blow molding machine is a kind of plastic processing equipment.

Working principe: After the liquid plastic is sprayed out, the wind blown out by the machine is used to blow the plastic body into a mold cavity of a certain shape to make a finished product.

The blowing materials of the blow molding machine can be selected from polyethylene, polyvinyl chloride, polypropylene, polystyrene, linear polyester, polycarbonate, polyamide, cellulose acetate and polyacetal resin. The product capacity produced can range from a few liters to thousands of liters, and the high-density polyethylene products produced can be widely used in food, chemical and liquid processing packaging.

The advantage of the blow molding machine is that the plastic containers formed by the blow molding machine have higher thickness, corrosion resistance and wear resistance. So it can replace some ceramic containers. In addition, the container cost of blow molded products is low, the processing difficulty is low, and the efficiency is high.

- Working principe of Bottle blowing machine

This bottle blowing machine is mainly used for produces bottles.

Working principe: The plastic particles are softened into a liquid and then blown into different bottles through the preform melt.

The containers produced by the bottle blowing machine are cheap and safe, so they are often used instead of glass containers in beverage, medicine, cosmetics, food processing and other industries.

Feature comparison

The blow molding machine is suitable for a wider range, and the bottle blowing machine is more suitable for producing some small plastic products. Below are the comparison:

- Blow molding machine has the characteristics of high thickness, corrosion resistance, wear resistance, etc. The die head adopts a chrome-plated screw mandrel structure to make the discharge more even and smooth, and better complete the blown film. The complex structure of the film blowing machine makes the output gas more uniform, and the lifting unit also adopts a square frame structure, which can be adjusted according to production needs.

- Bottle blowing machine: The main features of the hollow containers produced by the bottle blowing machine are light weight, low price and high safety. They are widely used in beverage, medicine, cosmetics, food and chemical industries. The equipment has strong mold clamping force and long service life, and is more suitable for the production of wide-mouth bottles.

If the container to be produced has a small capacity, it is better to choose a bottle blowing machine.

If it is a large plastic product, such as roadblocks, 1000L buckets, blow molding machines are better.

In conslusion

YG Machinery, as a professional blow molding machine manufacturer, can customize engine oil bottle making machines according to customer needs to produce high-quality products while ensuring the efficiency of the plastic blow molding machine. Therefore, our machines have been exported to 45 countries abroad. In the international market, the company’s large blow molding machines are deeply trusted by customers.