A meltblown machine is a method of blowing polymer solution through high-temperature and high-speed airflow to make it rapidly stretched to make fibers. The products it produces have many advantages such as sufficient filtration efficiency, low resistance, and softness, and the network can be combined and bonded by itself, after melt spinning, it is directly laid into a web to form a melt-blown non-woven fabric with unique properties. In many ways, its performance is better than other similar products.

Parameter of Meltblown Fabric Machine :

| Model | YGP-50 | YGP-65 | YGP-90 |

| Suitable raw material | 100% polypropylene | 100% polypropylene | 100% polypropylene |

| Length/Diameter ratio | 1:30 | 1:30 | 1:30 |

| Power | 7.5kw | 15kw | 37kw |

| Production capacity | 150kg/day | 150kg/day | 150kg/day |

| Center height | 1000mm | 1000mm | 1000mm |

| Speed of screw rotation | 20-120r/min | 20-120r/min | 20-120r/min |

| Voltage | 380V 50Hz | 380V 50Hz | 380V 50Hz |

If you are looking for a meltblown machine or meltblown nonwoven, YG Machinery will be your ideal partner. Send your requirement to us if you need to buy melt-blown nonwoven machine.

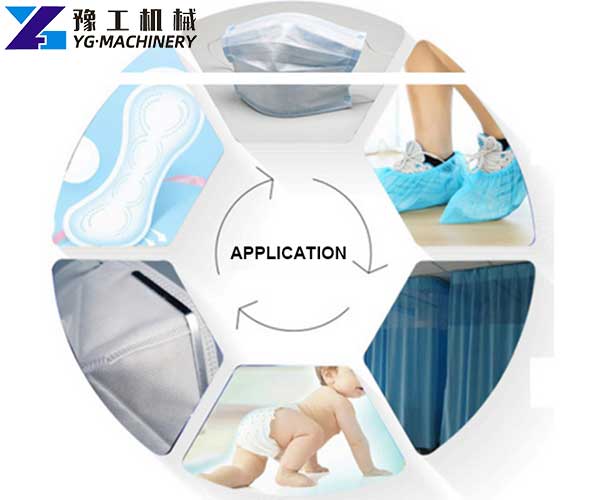

Scope of Application of Melt Blown Manufacturing Machine:

- Medical and sanitary cloths: surgical gowns, protective clothing, sterile cloths, masks, diapers, sanitary napkins, etc;

- Fabrics for home decoration: wall stickers, tablecloths, bedsheets, bed covers, etc;

- Clothing fabrics: lining, adhesive lining, flakes, shaped cotton, various synthetic leather base fabrics, etc;

- Industrial fabrics: filter materials, insulation materials, cement bags, geotextiles, covering fabrics, etc;

- Agricultural cloth: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc;

- Others: space cotton, thermal insulation, sound insulation materials, linoleum, cigarette filters, tea bags, etc.

Why is Meltblown Production Line so Important?

Because the melt-blown cloth can be used as the middle filter layer of the mask, in addition to blocking large dust particles, it can also attract fine dust, bacteria, and virus droplets through the electrostatic charge on the surface. It is an important raw material for the production of masks. It is the “heart” of the medical mask. It can be used in the fields of air, liquid filtration materials, insulation materials, absorption materials, mask materials, thermal insulation materials, oil-absorbing materials, and wipers. You can click the message box below or send an email to admin@ygroadmachine.com, Contact us to get meltblown machine price right now.

Advantages of Meltblown Nonwoven Machine:

- Short process flow and high production efficiency.

- The fiber is extremely fine and the hand feels soft. It has outstanding advantages in infiltration, antibacterial, and adsorption.

- Easy to operate and convenient for fully automatic production operation.

- Large demand, wide application range, and quick return on investment.

- Low energy consumption, stable operation, and long service life.

- Excellent price, best price, best quality guarantee.

Technical Characteristics of the Meltblown Machine:

- The air pressure of the air nozzle is stable, the airflow on both sides is symmetrical, and the airflow in the width direction is uniform.

- The air gap width can be adjusted.

- A special hot air flow heating device is adopted, which has good heating efficiency and excellent heat exchange efficiency, and low energy consumption rate.

- The accepted spacing can be adjusted, and the accepted form can be easily replaced.

- Auxiliary polarization treatment can make the melt-blown cloth have a good filtering effect.

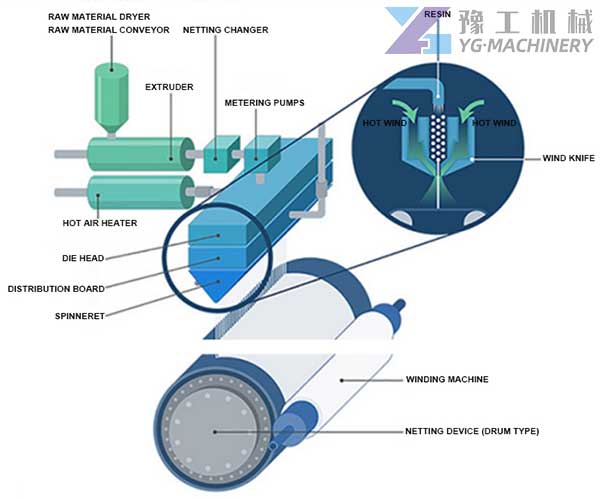

The Role of Each Component of the Meltblown Production Line:

- Screw extruder: Its main purpose is to melt the slice.

- Metering pump: Its function is to accurately measure, control the output and the fineness of the fiber, and continuously deliver the solution to the spinneret.

- Solution filter: Filter out impurities in the solution to prevent impurities from clogging the spinneret holes.

- Conveying net curtain: Spread the melt-blown fiber evenly on the net and convey it forward. There is a blower under it to discharge the hot air from below.

- Spinning box: It is the key equipment of the nonwoven fabric manufacturing process. It has a long spinneret plate, which is covered with spinneret holes. Hot air nozzles are installed on both sides of the spinneret and heat is installed underneath. After the air is sprayed out, the fiber is stretched with high-speed hot air to blow out the fiber and become an ultra-fine fiber.

- Feeding system: It consists of three hoppers, which are used to measure white slices, masterbatch, and additives. The three components enter the following mixing mixer and mix evenly, which is put into production.

- Hot air blower and heater: Provide the temperature and air pressure of the hot air used in the spinning airflow stretching, heated by electricity, and the power consumption is large.

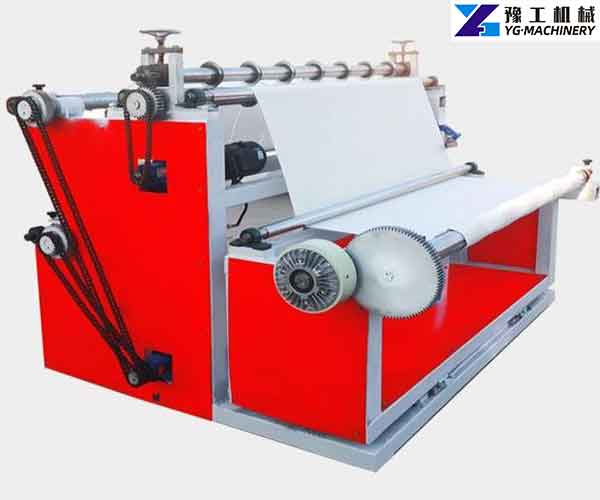

- The take-up machine uses a full-automatic take-up. The melt-blown cloth is packaged in rolls. The finer the fiber, the better the quality of the melt-blown cloth, but the relative output will also be reduced. Due to the ultra-fine fiber, its large surface area and strong adsorption capacity are the biggest characteristics of the meltblown nonwoven. Now contact us to get a cheap meltblown machine factory price.

Meltblown Machine Manufacturer

When choosing a meltblown machine, it is important to pay attention to several parameters, such as the production capacity of the equipment, the thickness range of the meltblown cloth, the width of the meltblown cloth, and the stability of the equipment. Whether it is an N95 mask or a disposable medical mask, it is indispensable. Therefore, the meltblown cloth is also called “the heart of the mask”. If you are looking for meltblown machine for sale, please leave your message.

A free consultation is welcome. Contact Us Now! WhatsApp/WeChat: +8613598866720.