Glove manufacturing machine is a piece of equipment to produce disposable gloves. As a fast consumable product, disposable gloves are used in almost every job in life. With the characteristics of non-toxic, odorless, waterproof, acid and alkali resistant, and oil resistant, it can prevent direct contact with various virus carriers and eliminate the chance of virus infection.

Remark: YG Machinery can also provide mask making machines and meltblown machines, wet wipe machines, oxygen concentrator machines, PSA oxygen generators, tissue paper making machines, and more epidemic prevention equipment.

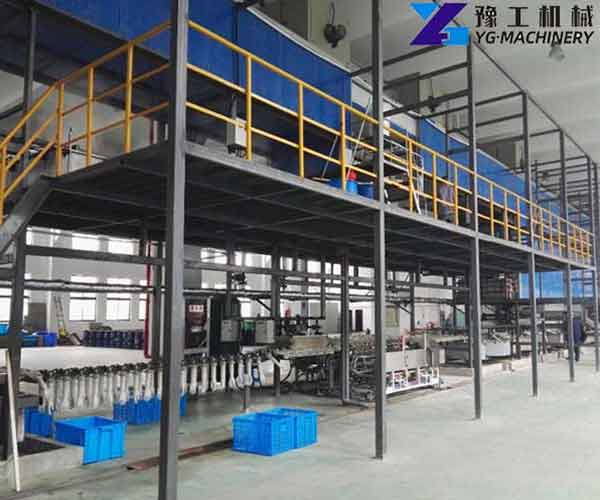

Gloves manufacturing machine for sale at best price

YG Gloves Making Machine is one of the best disposable gloves machines. Best price, high quality, the machine can produce 30k pcs per hour. Contact us for the glove manufacturing machine price.

Parameter of Disposable Gloves Making Machine

| Machine size | 110*1.8*16*10 layers*2 |

| Power | 190kw/hr |

| Speed | 25m/min |

| Production | 30,000pcs/hr |

| Heat consumption | 3,800,000cal/hr |

| Mould | 22,000pcs |

| Chain | 1,100m |

Classification of Glove Manufacturing Machine

There are many types of gloves on the market such as labor protection gloves, knitted gloves, latex gloves, and disposable film gloves. Gloves of different materials have different uses. Therefore, various glove manufacturing machines have also emerged.

YG machinery can provide several kinds of gloves production machinery:

- nitrile glove machine

- latex glove making machine

- PE glove making machine

- labor protection glove machine.

Which kind of disposable glove making machine are you interested in? Do not hesitate to leave your comment below.

Nitrile/Latex gloves manufacturing machine price

The latex/nitrile glove production line, with a high degree of automation, is suitable for a variety of formulations and can produce nitrile, latex, and PVC gloves. Nitrile gloves and latex gloves are two types of gloves widely used in industrial and agricultural production, medical treatment, and daily life. Because of the difference in materials, they have different properties and characteristics. Contact us to get nitrile/latex gloves making machine price here.

Disposable Gloves Making Machine

The plastic glove making machine, an ideal machine for producing plastic film gloves, is the main product of our company. PE is widely used in major hotels, guesthouses, medical and health care, family life, paint protection, beauty salons, garden work, cleaning work, etc. PE glove making machine is suitable for sealing and cutting high density polyethylene HDPE low density polyethylene LDPE plastic film into gloves.

Click the button to get the latest gloves making machine price.

Technical Characteristics of Glove Making Machine:

- Adopt the current glove production process layout and production process, the product qualification rate reaches more than 98%, and the protein content is less than 120 micrograms/gram;

- TPU coating technology;

- Imported surfactant coagulant, the film formation is more uniform, without powder release.

- Introduce the advanced transmission main chain structure from abroad, the chain running resistance is small, and the production runs smoothly at high speed;

- One main motor is dragged, which solves the problems of multiple drags, difficult synchronization, many fault points, and difficult maintenance;

- Vertical hot air circulation is adopted in the drying oven, which saves nearly 20% energy consumption compared with other forms of hot air circulation.

- Six-roller long-hair brush mold cleaning technology for cleaning the mold fingers;

- Mold orientation and onboard coding technology;

- Various specifications of the same machine production, automatic curling adjustment, PU curling roller, long service life;

- Models with different lengths, heights, and costs can be designed according to customer needs.

The glove manufacturing process – how are gloves made?

In fact, we can judge from the appearance of the gloves whether it is the same production method. Through comparison, we found that latex gloves, nitrile gloves, and PVC gloves use the same production method. It’s just that different raw materials and characteristics and uses are different. Therefore, a glove manufacturing machine using different mold parts can produce different gloves. Now contact us to get a glove manufacturing machine factory price.

How are gloves made? The glove model is first cleaned with acid and alkali and washed with water. The washed model is first immersed in hot water and heated to the coagulant and dried for dipping. After dipping, it is sent to the oven for preliminary drying, adding fiber inner sleeve, hot water, and then sent to the oven for vulcanization, drying, and forming. The gloves are inflated after demolding, low-temperature setting, medium temperature drying, washing, dehydration, drying, and then packaged and sent to the finished product warehouse.

Gloves Machine Manufacturer & Supplier

There are many types of glove manufacturing machines. The price, cost, and production process of different glove manufacturing machines are different. First of all, when we receive a call from a customer about a glove manufacturing machine, we must first confirm with the customer what kind of glove material is to be made, and what is the purpose of the glove. The second is to recommend suitable glove making machines to customers based on their budget and needs. Contact us now for more sales information on the YG disposable gloves making machine.

YG Machinery has always provided customers with high-quality products and competitive prices. Welcome to visit our factory. We not only have glove making machine but also rubber balloon production line, etc. Please feel free to leave your messages below if you have any questions about the gloves machine.