With the continuous progress of society and the continuous improvement of people’s living standards, people are paying more and more attention to their own health conditions, leading to a sharp increase in market demand for health care oxygen and medical oxygen. An industrial oxygen generator is a kind of equipment that uses air as raw material and uses the principle of pressure swing adsorption to provide medical oxygen to hospitals and medical institutions. It has the characteristics of small size, fast start-up, low energy consumption, simple operation, and large load operation adjustment range.

In addition, about us, YG Machinery can not only provide you with an oxygen concentrator machine. But also nitrogen generator for sale, glove making machines, meltblown machines, mask making machines to choose from. Now contact us to get a cheap industrial oxygen generator factory price.

Parameter of Oxygen Gas Generator:

| Model No. | Flow Rate | Purity |

| YGFO-5 | 5 | 93±2% |

| YGFO-10 | 10 | 93±2% |

| YGFO-20 | 20 | 93±2% |

| YGFO-30 | 30 | 93±2% |

| YGFO-40 | 40 | 93±2% |

| YGFO-50 | 50 | 93±2% |

| YGFO-60 | 60 | 93±2% |

| YGFO-70 | 70 | 93±2% |

| YGFO-80 | 80 | 93±2% |

| YGFO-100 | 100 | 93±2% |

| YGFO-120 | 120 | 93±2% |

| YGFO-150 | 150 | 93±2% |

| YGFO-180 | 180 | 93±2% |

| YGFO-200 | 200 | 93±2% |

Working Principle of Industrial Oxygen Generator:

The PSA oxygen generator system uses molecular sieve technology to separate oxygen from the air, using dry and clean air as raw material, using zeolite molecular sieve as adsorbent, and using zeolite molecular sieve to increase the adsorption capacity of nitrogen when pressurized at room temperature. The characteristic of reducing the amount of nitrogen adsorption during decompression, forming a cycle of pressure adsorption and decompression desorption, separating 78% nitrogen and 21% oxygen in the air to produce oxygen, completing the separation of oxygen and nitrogen, and obtaining the required purity oxygen.

Product Features of Industrial Oxygen Generator:

- The whole set of equipment can be started and stopped at any time, with short start-up time, strong reliability, convenient operation, complete monitoring equipment, almost unmanned operation, just press the button to start and close, and the start-up takes between 10-30 minutes It can produce qualified oxygen.

- The equipment is easy to check and repair, with few wearing parts, imported analyzer online detection, high precision, and maintenance-free.

- The oxygen purity is easy to adjust. The oxygen purity is only affected by the amount of oxygen discharged. The purity of ordinary oxygen generators can be adjusted between 85% and 90%, and the high purity oxygen generators can be adjusted between 90% and 95%.

- Adopt advanced PLC control or data acquisition monitoring system, and the reserved interface can be remotely monitored with computers.

- Scientific structure design and special gas diffusion devices avoid the high-speed impact of gas flow and the phenomenon of molecular sieve powdering.

- The use of an internal balance automatic compression device and unique molecular sieve filling technology improves the reliability of the long-term operation of the whole machine.

- Automatic interlocking oxygen emptying device to ensure product oxygen quality.

How Much is the Industrial Oxygen Generator?

The industrial oxygen generator is also called air separation equipment. According to the number of products, it can be divided into small equipment below 800m3/h; medium equipment from 1000-6000m3/h; large equipment above 10000m3/h. The oxygen produced by the PSA oxygen generator has incomparable advantages such as high concentration, naturalness, cleanliness, environmental protection, safety, and low cost. According to users’ different requirements for oxygen use, YG Machinery provides professional oxygen production equipment to fully meet the gas requirements of different users. Contact us to get an industrial oxygen generator price right now.

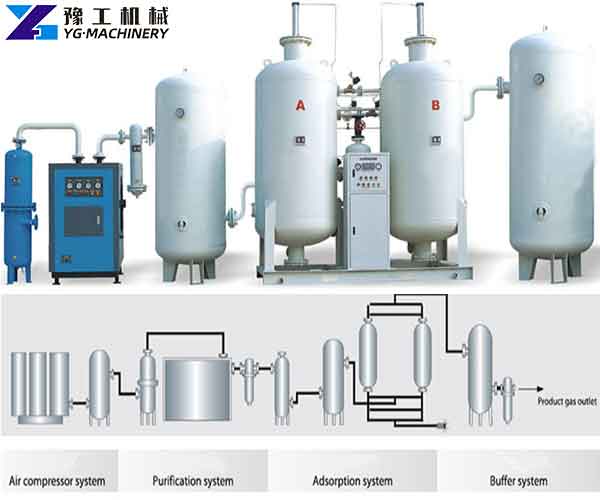

PSA Oxygen Generator of Composition

Composed of air compressor, air storage tank, refrigeration dryer filter group, adsorption dryer, air buffer tank, dealer, oxygen system, and oxygen tank.

- Air compressor: The air compressor provides raw air for the entire system. According to the air output of the PSA oxygen generator, an air compressor that meets the design conditions is selected for air supply.

- Cold dryer: After the air compressor pressurizes the raw material air, the high temperature and high pressure compressed air enters the cold dryer for cooling, drying, and impurity removal to obtain low temperature and high pressure compressed air.

- Drying machine: the compressed air uses the difference between the moisture and the volume of air molecules, and the special molecular sieve for gas purification is used to filter out the saturated water vapor in the compressed air, which can easily absorb the water molecules in the molecular sieve particles and reuse the regeneration method To reduce the molecular sieve, its compressed air dew point can easily reach -40℃ to -70℃.

- Degreasing device: The degreasing device removes the oil mist in the low-temperature and high-pressure compressed air to prevent the oil mist in the air from affecting the life of the zeolite molecular sieve.

- Oxygen production system: The adsorption system consists of two adsorption towers and pipeline valves equipped with zeolite molecular sieve adsorbents. The low-temperature and high-pressure compressed air enter from the bottom of Tower A. When it flows through the adsorbent layer, nitrogen, carbon dioxide, and water vapor in the air are adsorbed. The oxygen is collected through the adsorption bed to the top of the adsorption tower as a product gas output. At the same time, Tower B is in regeneration mode. When the adsorption tower performing adsorption is about to reach adsorption saturation, under the adjustment of the control system, the low-temperature and high-pressure air are transferred to Tower B to start adsorption and oxygen production. Towers A and B alternately achieve the purpose of continuous oxygen production in this way.

Other Products

YG Machinery Company sells various construction machinery. For example, DTH drilling rigs, water well drilling rigs, small water well drilling rigs, core drilling rigs, hydraulic rock splitter, pile breaker, mini roller machine, shot blasting machine, mortar sprayer machine, automatic sandblasting machines, fog cannon machine, etc. Contact us to get the price list.