Road construction projects require a variety of specialized machinery to ensure efficiency, safety, and quality. From building new roads to maintaining existing highways, the right road construction machinery can save time and costs while improving results. This article provides a comprehensive list of essential road machinery used in modern infrastructure projects, highlighting their functions, applications, and advantages for contractors.

Road Construction Equipment For Site Preparation

Before paving or laying, the construction site must be properly prepared. Key road construction machinery used in site preparation includes:

- Motor Grader – Used to create a flat, level base for roads. It ensures that the subgrade is smooth and ready for compaction or paving.

- Bulldozer – Moves large quantities of soil, debris, or rock, helping to shape the terrain for road construction.

- Road Compactor / Vibratory Road Roller – Compresses soil and subgrade materials to increase stability and strength.

- Pneumatic Tire Roller – Provides even compaction using rubber tires, ideal for fine grading and final surface preparation.

Asphalt Road Construction Machinery

Asphalt roads require specialized machinery to guarantee smooth surfaces and long-lasting durability. Key equipment includes:

- Asphalt Paver – Lays asphalt evenly on the prepared subgrade, creating a smooth road surface ready for compaction.

- Asphalt Mixing Plant – Produces hot-mix asphalt with consistent quality and proper temperature control.

- Asphalt Distributor – Sprays bitumen evenly across the surface to ensure proper adhesion of asphalt layers.

- Chip Sealer – Applies a layer of aggregate over asphalt to strengthen and protect the surface.

- Asphalt Recycling Equipment – Recycles old asphalt material to reduce waste and cost while maintaining road quality.

Concrete Road Construction Machinery

Concrete roads require precise equipment for pouring, finishing, and curing. Essential machinery includes:

- Concrete Paver – Spreads and levels concrete uniformly to form the road surface.

- Slipform Paver – Creates joint-free, smooth concrete surfaces using a continuous molding process.

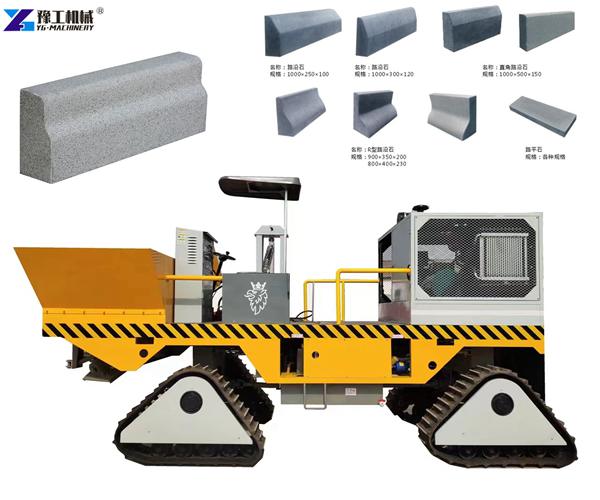

- Curb Slipform Machine – Produces curbs for road edges and channels, ensuring consistent shape and quality.

- Concrete Road Saw – Cuts concrete joints to control cracking and improve durability.

- Concrete Grooving Machine – Creates grooves on concrete surfaces to improve traction and water drainage.

- Power Trowel – Smooths and polishes freshly laid concrete for a finished surface.

- Shotcrete Machine – Sprays concrete for walls, overlays, or repair work, providing strong adhesion and coverage.

Road Surface Treatment And Maintenance Equipment

Maintaining roads is critical for safety and longevity. Common machinery includes:

- Road Grinding Machine – Removes uneven surfaces or old pavement layers to prepare for resurfacing.

- Road Sweeper/Vacuum Cleaner – Cleans debris, dust, and loose materials from roads to improve safety.

- Crack Sealing Machine – Fills road cracks to prevent water infiltration and further damage.

- Road Repair Machine – Efficiently handles potholes and localized repairs.

- Road Polishing Machine – Restores surface smoothness and improves road aesthetics.

- Road Line Removal Machine – Removes old traffic lines for repainting or redesign.

Road Marking And Traffic Safety Machinery

Proper road markings and safety equipment are essential for traffic management. Key machinery includes:

- Thermoplastic Road Marking Machine – Applies durable road markings that withstand heavy traffic.

- Cold Paint Road Marking Machine – Uses paint for temporary or low-traffic markings.

- Two-Component Road Marking Machine – Ensures high-quality reflective road lines for night and wet conditions.

- Traffic Cone Making Machine / Traffic Barrier Making Machine – Produces cones and barriers to improve safety at construction sites.

Road Cutting And Demolition Equipment

Some road renovation projects require cutting and demolition. Essential equipment includes:

- Road Cutting Machine / Floor Saw – Cuts asphalt or concrete precisely for repairs or new layouts.

- Hydraulic Wall Saw / Wire Saw Cutting Machine – Handles thick concrete walls or complex structures efficiently.

- Concrete Breaker / Hydraulic Hammer – Breaks concrete for removal or reconstruction tasks.

Auxiliary Road Construction Equipment

Additional machinery supports road construction and improves workflow efficiency:

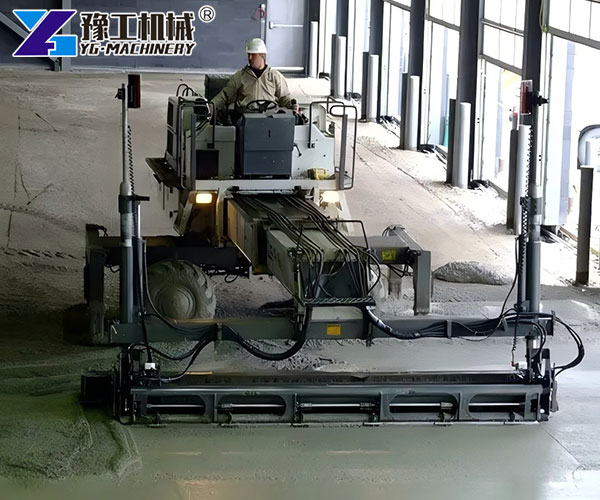

- Vibrating Screed – Levels freshly poured concrete to a uniform height.

- Concrete Placer – Distributes concrete efficiently for large slabs or high-volume projects.

- Construction Generator / Air Compressor – Provides power and air supply for various on-site equipment.

- Lighting Tower / Dust Suppression Truck – Ensures safety and environmental compliance during night work or dusty conditions.

Why Choosing The Right Road Construction Machinery Matters

Using high-quality road construction machinery reduces construction time, lowers operational costs, and improves road quality. Contractors should select equipment based on:

- Road type: asphalt or concrete

- Project scale: small urban roads versus highways

- Working environment: indoor, restricted space, or extreme temperatures

- Maintenance and operator training requirements

Proper planning ensures machinery investments deliver long-term value and efficient operations.