How are made umbrellas? Do you want to start an umbrella manufacturing factory? If you need to get more details about the Umbrella Making Machine, please leave your contact information. We will reply to you as soon as possible.

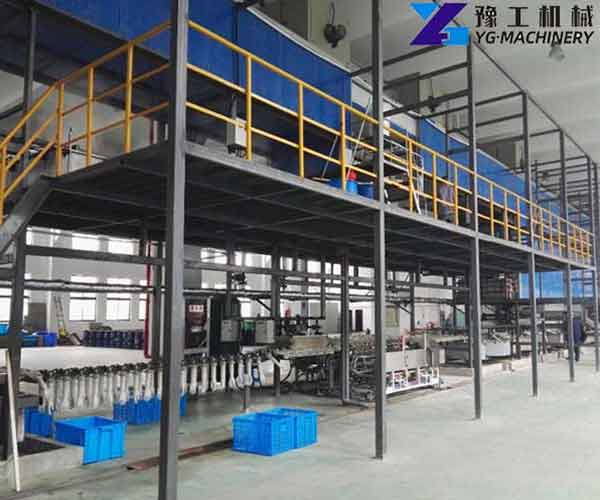

Full Automatic Umbrella Making Machine

Umbrella making machine is based on the research status of the high degree of manual production and low degree of mechanized continuous production in the umbrella production process and proposes a solution to design a set of umbrella automated production lines with complete processes and continuous production. Various related equipment and non-standard automation equipment can be individually designed and manufactured according to the needs of customers to meet the needs of customers in actual production.

Umbrella Cloth Cutting machine for sale

We have also a machine for manufacturing transparent umbrellas. If you want to get the transparent umbrella making machine, please contact us to get a free quote.

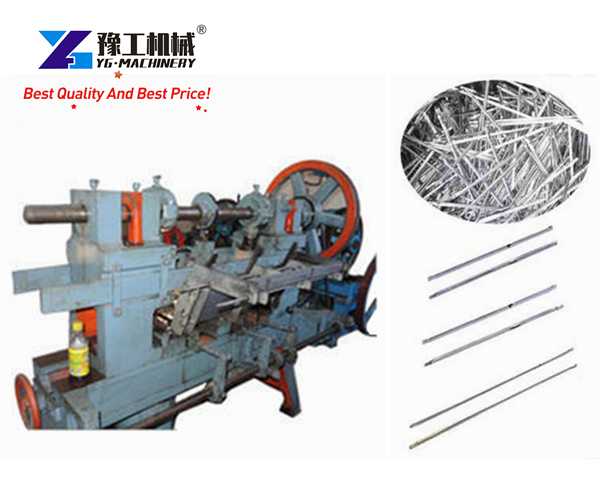

Automatic Umbrella Ribs Making Machine

Working Principle of Umbrella Making Machine:

The main feature of the umbrella making machine is that the production line evenly distributes three sets of reclaiming devices. These three sets of devices arrive at the predetermined position at the same time, which improves the production efficiency of the automated assembly line.

Secondly, according to the design index of the umbrella tail automatic assembly line to assemble 18 umbrella tails per minute. The umbrella bead automatic feeding device feeds 30 times per minute. And you can select sizes for several different types of umbrella tails and umbrella beads. The machine can assemble the umbrella automatically. The parameters of the control components are designed and calculated.

Umbrella Stitching Machine

The umbrella stitching machine is a single needle lockstitch sewing machine that pursues high-speed sewing. The key parts of the mechanism have been greatly improved. So that the machine can truly obtain stable and ideal stitches in high-speed sewing. Even if the sewing speed changes, the stitches can still be kept uniform and tidy. In terms of noise and use, it is also significantly better than other models.

Features of Umbrella Making Machine:

- The imported PLC servo operating system is adopted to ensure the smooth operation of the machine.

- Tension-free cloth operation, no stretching, wind resistance, noise reduction, and vibration reduction.

- Simple setting of machine operation, single-person operation, saving manpower, without excessive manual intervention.

- Emergency stop device. When an emergency stop is made, the lowered fabric will not be dragged, and it will automatically stop if there is no fabric, or it will automatically stop when the set number of layers is reached.

- Automatic edge alignment device, the fabric edge is even, saving fabric.

- With a material collection device, the cloth laid on the cutting table can be rolled back.

- The cutting knife path is adjusted according to the width of the fabric, which saves unnecessary lap time. It can be spread in one direction or in both directions.

Umbrella Manufacturing Process | How an Umbrella is Made?

- Umbrella cloth processing: generally cut the umbrella cloth and combined pieces in the finished product workshop;

- Umbrella rib processing: the umbrella frame includes two parts, the middle rod and the rib that prop up the umbrella surface. First, process the middle rods in the middle rod workshop, and then electroplate them in the electroplating workshop; meanwhile, assemble the umbrella ribs in the umbrella bone workshop;

- Handle processing: handles made of polypropylene and other plastic materials are injection molded by an injection molding machine in the injection molding workshop, and then sent to the finished product workshop or self-development workshop for assembly;

- Umbrella sewing: transport the finished umbrella surface, middle rod, umbrella rib, and umbrella handle to the finished product workshop. Then assemble the middle rod and umbrella rib into an umbrella stand in the finished product workshop. The umbrella sewing worker will assemble the umbrella cloth and umbrella ribs. Finally, the umbrella head and the middle rod are assembled.

What Materials are Used to Make an Umbrella?

There are four main types of fabrics for umbrellas, with the cost from low to high: polyester, PG cloth, nylon, and transparent plastic. Transparent umbrellas, popular in recent years, are made of POE or PVC plastics. The waterproof cloth is an ordinary cotton cloth treated with water repellent. The waterproofing agent is a kind of paraffin emulsion slurry containing aluminum salt. After the paraffin wax is emulsified, it becomes fine particles evenly distributed on the cotton fiber. Whoever can’t make the paraffin wax, when the water touches the paraffin wax, it turns into oval water droplets and rolls on the paraffin wax. So the umbrella will not leak.

In terms of umbrella frame materials, to meet the needs of portable umbrella products, it has developed from traditional steel bones to aluminum alloy bones, glass fiber bones, carbon-fiber bones, and even titanium alloy bones, enhancing its functions to a new surface.

Umbrella Making Machine Manufacturers

YG Machinery’s products have excellent quality and super cost-effective advantages. They are products that customers can choose to reduce costs and improve quality. Of course, our company not only owns umbrella making machines but also packing machines, rewinding machines, etc. Choosing YG Machinery will get the best product quality and the most competitive price.