The asphalt crack sealing machine is a special maintenance equipment for road cracks. It can accurately inject sealing materials into the cracks to form a strong sealing layer. Compared with traditional tools, it has higher operating efficiency and a longer-lasting sealing effect. The equipment has a wide range of applications and can handle cracks in both asphalt roads and cement roads, whether it is a hairline crack or a few centimeters wide crack, it can deal with it efficiently. Looking for a high-quality road crack filling machine? Click to get a discount price!

Asphalt Crack Sealing Machine Parameter

| Model | YG-50L | YG-80L | YG-100L |

| Hopper volume | 50L | 80L | 100L |

| Discharge method | Self flow | Asphalt pump feed | Asphalt pump feed + hand-held tube |

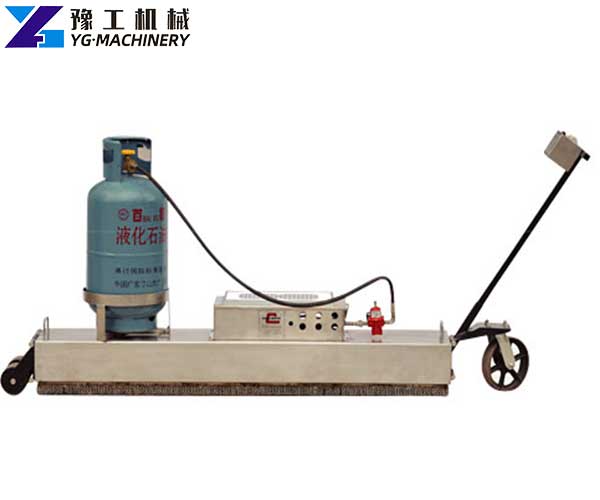

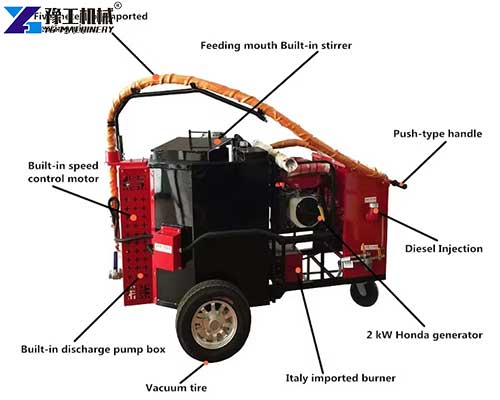

| Heating method | Liquefied gas | Liquefied gas + heat transfer oil | Italian diesel burner, heat transfer oil cycle heating |

| Temperature control | Temperature sensor 180 ° (temperature control call) | Temperature sensor 180 ° (temperature control call) | Automatic temperature control system |

| Filling speed | 10m/min | 15m/min | 20m/min |

| Length of sealing pipe | —— | —— | 5m |

| Walking mode | Push-type + brake device | Push-type + brake device | Push-type + trailer |

| Mixing method | Manual mixing | Manual mixing | Electric stirring |

| Power Configuration | Solar panels + batteries | Solar panels + batteries | Import 2KW generator |

| Dimensions | 1200*700*1200mm | 1200*700*1200mm | 1750*786*1200mm |

| Weight | 120kg | 150kg | 220kg |

Structural Features of Asphalt Crack Filling Machines

The asphalt crack sealing machine adopts a sophisticated design, and its core consists of three parts.

- The heating system can quickly melt the sealing material and maintain a suitable temperature to ensure that the material remains smooth during the injection process.

- The conveying device can accurately control the material flow rate, which can be flexibly adjusted according to the crack size to avoid material waste and ensure uniform sealing.

- The operating handle is designed to be light and flexible, which is easy for the operator to control. The handle is integrated with control buttons for convenient start and stop.

- Compared with other asphalt crack filling machines, its structure is more compact and easy to transport. It can be loaded on ordinary trucks and can adapt to special operation scenarios such as narrow roads.

Workflow of Crack Filling Machine

The operation process of crack sealing machine is divided into four steps.

- It is crack cleaning. A hair dryer or brush is needed to remove dust and gravel in the crack. The residual debris will directly affect the sealing effect.

- It is crack preheating. The machine has a preheating function that can increase the temperature around the crack and enhance the bonding between the material and the road surface.

- It is material injection. After starting the equipment, the melted material is injected into the crack. The injection amount should be slightly higher than the road surface.

- It is cooling and molding. The material solidifies within a few minutes, and the road surface can be restored to traffic. The whole process is efficient, and it only takes a few hours to deal with cracks in a section of road.

When Should the Crack Filler Be Used?

When the road surface has the following conditions, the asphalt crack filling machines need to be used for treatment.

- The temperature drop before winter can easily cause the road surface to shrink and crack. Sealing in advance can effectively avoid the impact of frost damage.

- Before the rainy season, it is necessary to seal the cracks to prevent rainwater from seeping into the roadbed and protect the stability of the road surface structure.

- When a large number of small cracks appear on the road surface, the use of crack filler for batch operation can greatly improve the processing efficiency, which is better than single-crack processing.

The use of this equipment can reduce the frequency of road overhauls and achieve a small investment in exchange for large returns.

Cost-Benefit Analysis of the Road Crack Filling Machine

- The cost of purchasing a crack filler is controllable. Compared with road overhaul, the investment gap is dozens of times.

- It can reduce the number of repeated maintenance. One sealing can last for 3-5 years, which is much longer than the effective period of about 1 year of ordinary methods. It can significantly reduce the maintenance cost in the long run.

- The equipment has outstanding operating efficiency and can process thousands of meters of cracks in a single day. Compared with manual processing (several people process less than 100 meters in a single day), it can greatly reduce the time cost.

The pavement crack filling machine produced by YG is more cost-effective, with more advantageous prices and stable effects. You are welcome to click here to get the details of the machine now!

Choose YG, Choose Affordable

YG is a professional pavement crack filling machine manufacturer, and the asphalt crack sealing machine it produces has both excellent quality and affordable prices. The equipment is made of high-quality steel, with strong durability, and the core components are imported configurations with stable performance. At the same time, we provide a perfect after-sales guarantee. If there is any problem with the equipment, you can contact us at any time, and the technicians will help you solve the problem in time. YG’s asphalt crack filling machines can simplify the pavement maintenance process and improve the durability of the pavement without high investment. We also produce pavement marking machines, pavement shot blasting machines, laser leveling machines, and other related equipment. If you need to get a quote for equipment, contact us now!