The slipform curb machine is special equipment for efficiently forming curbs in road construction. It integrates hydraulic drive and mold shaping. The equipment directly injects concrete into the mold and forms the curb in one go through processes such as vibration and extrusion. The curb and gutter machine can greatly shorten the construction period and improve the integrity and strength of the curb. Click here to get a high-quality quote for the curb slipform machine!

Slipform Curb Machine Parameters

| Model | KB20 |

| Machine size | 5200L*2400W*2800Hmm |

| Machine weight | about 7000kg |

| Engine | inline 4-cylinder turbocharged diesel engine |

| Construction range | width ≤2000mm (road shoulder, ditch); height ≤600mm (curbstone, curbstone) |

| Forming method | high-frequency vibrator, attached vibration motor |

| Automatic leveling system | leveling range ±40mm |

| Paving, transfer speed | 1m-10m/min (frequency conversion speed regulation) |

| Model | KB30 |

| Machine size | 5200mmL*2400mmW*2900mmH |

| Construction range | width ≤2000mm; height <=1100m |

| Rated power | 65KW |

| Working voltage | AC38Ov |

| Starting mode | electric start |

| Cooling mode | water cooling |

| Forming method | high-frequency vibrator, attached vibration motor |

| Automatic leveling system | leveling range ±40mm |

| Minimum turning radius | 6800mm |

| Paving and transfer speed | 1m-10m/min |

Application Scenarios of Curb and Gutter Machine

- The curbs on both sides of the highway must be straight and flat. The slipform curb machine is the most suitable, making hundreds of meters a day.

- The community’s sidewalk boundaries may be curved or straight. The machine can turn flexibly and make smooth lines.

- You can also change the special mold to make a patterned curb on the side of the small road in the park, which is both practical and beautiful.

- The curb and gutter machine is similar to it, but it can also make drainage ditches at the same time, which is suitable for places with heavy rain and a need for drainage.

- It can be used as a boundary for rural roads to make the road surface more regular and prevent rainwater from eroding the roadbed.

Hot-Selling Kerb Laying Machine Features

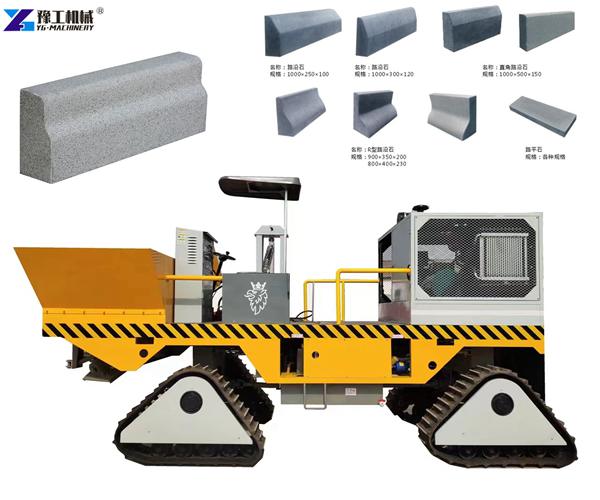

Currently, YG’s hot-selling curb slipform machine models are the eight-wheel KB20 and the large four-track KB30. Their features are as follows:

- Continuous casting of curbs: This is its core function. It can extrude straight or curved concrete curbs in one go and continuously along a preset route.

- Efficient construction: Compared with the traditional method of manual prefabrication, transportation and installation, the slipform construction speed is extremely fast and greatly shortens the construction period.

- Ensure linearity and consistency: The machine is guided by lasers or wires to ensure that the height, linearity and cross-sectional shape of the formed curbs are highly accurate.

- Improve the integrity of the structure: The curbstone formed by continuous casting on site is a seamless whole with high structural strength, and is not prone to misalignment, looseness or damage at the joints of traditional prefabricated blocks.

- Reduce costs: Although the equipment investment is large, due to its extremely high construction efficiency and saved labor, prefabrication, transportation and installation costs, the overall cost is usually lower in large projects.

How to Get a Concrete Border Machine Model That Suits You?

To get a curbstone slipform machine model that suits you, you need to consider many factors.

- First, clarify the construction requirements, including the scale of the project, the specifications and dimensions of the curbstone, the shape and style, etc. For large-scale and complex projects, you need to choose a model with strong performance and full functions.

- Secondly, consider the construction environment. When the terrain is complex and the site is narrow, you should choose a flexible, convenient and adaptable model.

- In addition, the budget is also critical. Choose a cost-effective product within an affordable range.

- In addition, consult your peers for experience and refer to professional reviews to understand the performance of different models in actual use. After a comprehensive comparison, you can choose the model of curb slipform machine that fits your construction conditions and meets the needs of the project.

Slipform Curb Machine for Sale- YG Machinery

The slipform curb machine made by YG is of good quality and has been sold to many countries such as the UAE, Iraq, Cambodia, Saudi Arabia, Russia, Romania, Costa Rica, etc. Customer feedback is very good, saying that the machine is durable and rarely breaks down. Whether you want KB20 or KB30, or other models, we have them. We also make concrete border machines, which can meet various construction needs. The price is fair; the same machine is about 30% cheaper than imported brands, and the functions are practical. Customers who have used it say it’s good. We also provide free mold design services and can customize exclusive molds according to your drawings. In addition, we also produce road marking machines, road shot blasting machines, road crack filling machines, road rollers, laser leveling machines, and other equipment.Click now to get a machine quote. Don’t hesitate, act quickly!