Yes, asphalt millings can be sealed to help protect them and prolong their lifespan. Sealing the surface of the millings can also enhance their appearance and provide a smoother surface for driving or walking.

To seal asphalt millings, you will need to follow these steps:

- Clean the surface: Remove any debris, dirt, and dust from the surface of the millings using a broom, blower, or pressure washer.

- Repair any cracks: Use a crack filler to repair any cracks or holes in the surface of the millings. Allow the filler to dry completely before proceeding.

- Apply the sealant: Apply a thin layer of sealant to the surface of the millings using a squeegee or roller. Be sure to apply the sealant evenly and avoid over-applying in any areas.

- Allow to dry: Allow the sealant to dry completely before using the surface.

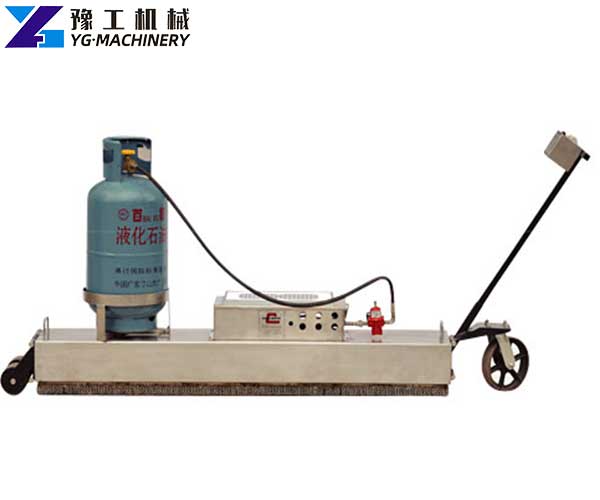

YG-100 Crack Filler Machine

- Model: YG-100

- Filling Capacity: 100L

- Heating Time: 30-40min

- Temperature Range: 0-200°C

- Discharge Capacity: 8 L/min

- Generator: Honda 2kw

- Walking Mode: Manual or Traction

- Burner: Riello 445T1 Diesel Engine

- Dimension: 2000*1000*1300mm

- Weight: 400kg

How do you prepare an asphalt driveway for sealing? | Asphalt Millings

Here are the general steps to prepare an asphalt driveway for sealing:

- Clean the driveway: Sweep the driveway thoroughly to remove any loose debris, dirt, and leaves. Use a leaf blower or a broom to clear the surface. Then, use a pressure washer to clean the surface of the driveway and remove any oil or grease stains. Let the surface dry completely before proceeding to the next step.

- Fill any cracks: Inspect the driveway for any cracks or holes. If you find any, use a crack filler to fill the gaps. Smooth the filler using a putty knife or trowel. Let the filler dry completely before proceeding to the next step.

- Patch any potholes: If there are any potholes on the driveway, fill them with a patching compound. Follow the manufacturer’s instructions carefully while mixing and applying the patching compound.

- Repair any damage: If there are any areas on the driveway that are damaged, repair them using an asphalt patching compound. Apply the compound evenly and use a trowel to smooth it out.

- Apply sealant: Once the driveway is completely dry and all repairs have been made, you can apply the sealant. Choose a high-quality asphalt driveway sealer and follow the manufacturer’s instructions carefully. Use a squeegee to spread the sealant evenly across the driveway.

- Allow to dry: Allow the sealant to dry completely before using the driveway. Depending on the weather conditions, this can take anywhere from a few hours to a few days.

Note: It’s recommended to seal an asphalt driveway every 3-5 years to maintain its appearance and protect it from the elements.

Henan Yugong Machinery Co.,Ltd

Henan Yugong Machinery Co.,Ltd, also named YG Machinery, is a top, professional, and reliable machinery manufacturer. The main types of machinery we produce include bridge and road machinery, drilling equipment, mining equipment, tunnel construction machines, grouping pump equipment, environmental protection equipment, etc.

If you are interested in our machine, please contact us by WhatsApp or Email. We will reply to you as soon as possible. Whatsapp/Wechat/Skype/Phone: +8613598866720.