The drilling rig is a equipment that is usually used for the construction and mining. There are too many types of drilling machines. How to choose a right drill rig? Here, we will introcethe tips on how to choose a right drill, drill bits and drill pipe.

How to choose a right drill rig?

Maybe you need a drill rig for multiple purposes, such as drilling for natural resources (water, oil, geothermal energy, etc.), for construction, blasting holes in mines, or for taking Mineral samples, etc. Below are steps on hoe to choose a right drill.

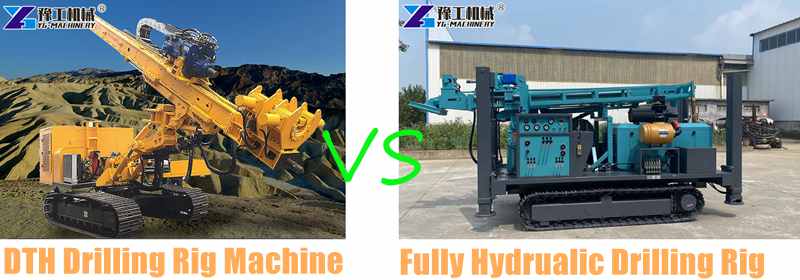

First of all, you have to determine what work this rig will be used for and what will be the main material when drilling. Depending on the terrain and material, you can choose different types of drilling rigs: rotary drilling rigs, impact drilling rigs, down-the-hole drilling rigs, top hammer drilling rigs (with high hammer), etc.

It is also important to define the type of mobility you will need. There are autonomous crawler drilling rigs and truck-mounted or trailer-mounted drilling rigs that need to be powered by a generator or the truck that carries them.

Once you have determined the type of machine you need, you can calculate the size required according to the diameter and depth of the borehole.

Check the sheet below on how to choose a right drill bit:

After the tips on how to choose a right drill, you maybe need to know how to choose a drill bit. Read on.

How to choose a suitable drill bit?

When choosing the right drill bit for your drilling rig, you should pay attention to the following points:

- When producing soft rock with good drillability, the drilling speed is faster and a large amount of slag discharge and high-quality slag discharge must be selected, and the shape of the four wings is preferably selected.

- When producing hard rock, due to the high strength of the rock, each column tooth and drill bit needs to bear a lot of loads. Therefore, it is necessary to select a drill bit with a higher strength drill body and stud teeth.

- When drilling rock with clay, the slag holes often appear to be blocked due to the loosening of the clay, and a side slag bit can be selected.

- The toughness is better when drilling on the rock, and the toothed bit can be selected to ensure safe production.

How to choose a good drill pipe?

Many people often ask about the matching of drill pipe and drilling rig, or the use of drill pipe, etc., but few people ask how to choose a good drill pipe. This is because the public generally chooses low-priced items at will when purchasing, so it is not so handy in actual use. Here, I will explain to you how to choose a good drill pipe.

- First of all, we have to figure out what the drill pipe we bought is going to be used for. Because different drill pipes have different functions, for example, geological drill pipes are mainly used for water exploration, gas exploration, coal exploration, etc.; geological auger pipes are mainly suitable for deep hole drilling construction with geological conditions above medium hard, with slag discharge Function; high-efficiency auger pipe is suitable for drilling construction of water exploration and gas exploration under the geological conditions of coal seam and near coal seam, and has the characteristics of light weight, fast connection, fast slag discharge, etc. The three-edged drill pipe is the first choice for deep hole drilling in soft geology and soft coal seam.

- In addition to the variety of drill pipes, there are various types of drill pipes. The choice of drill pipe is related to the torque of the drilling rig, so we should choose the appropriate type of drill pipe and drill bit according to different geological conditions and drilling depths.

That’s all. Now, you know how to choose a right drill rig machine, suitable drill bits and drill pipe. If you need the drilling rig equipment or drill bits, drill pipe, please leave your messages, our sales manager will make a quotation for you. Contact us Now! WhatsApp/WeChat: +8613598866720.