Congratulations! YG Concrete pile cutting machine was successfully exported to UAE. Concrete pile cutter machines have emerged as vital tools in the construction and demolition industries, revolutionizing the way concrete piles are handled.

Get a quote now! Find out how our pile breakers can improve the efficiency of your project, click here to request a personalized quote.

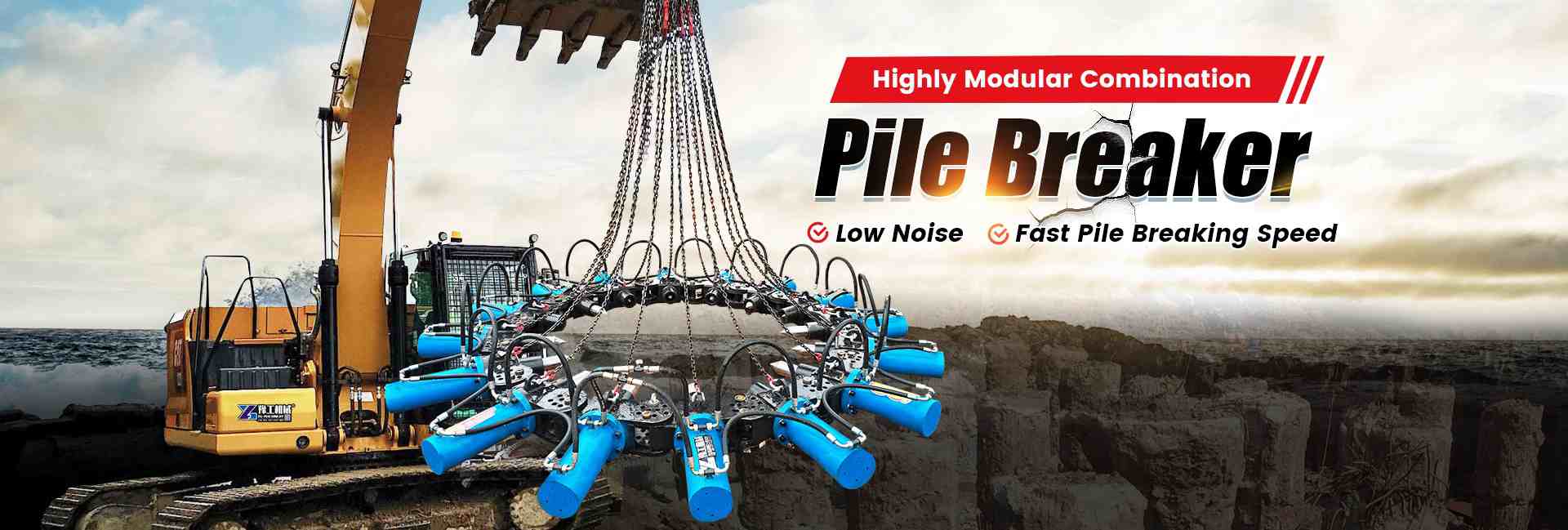

Choose the suitable pile cutter for your project

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Singlemodule weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Singlemodulesize | 1015*865*340mm | ||||||||

Case in UAE: Successful Applications of Concrete Pile Cutting Machines

YG Hydraulic concrete pile breaker was used for the construction of Dubai Metro Blue Line. The 30km line will connect Dubai International Airport with the surrounding densely populated areas. To accommodate the construction of the new station, the existing concrete piles needed to be modified. The contractor used an advanced hydraulic concrete pile cutting machine to quickly and accurately break the piles, thereby speeding up the reconfiguration of the site boundaries.

Choosing the Right Size and Type of Concrete Pile Cutting Machine for Your Project

When embarking on a construction project that requires the use of concrete piles, selecting the appropriate concrete pile cutting machine is crucial for ensuring efficiency and precision. The first step in this process is understanding the size of the piles you will be working with. Concrete piles come in various dimensions, and the cutting machine must be capable of accommodating these specifications. For smaller projects with less demanding pile sizes, a compact or portable machine might suffice. However, larger structures often necessitate robust equipment that can handle significant workload without compromising accuracy.

Beyond size, the type of concrete pile cutting machine also plays a vital role in how effectively a project proceeds. These machines come in various designs, including hydraulic and mechanical models, each offering distinct advantages. Hydraulic machines, for instance, tend to provide smoother cuts and greater control, making them suitable for projects demanding a high level of precision. On the other hand, mechanical machines, while possibly less expensive, might require more manual intervention and skill, which can affect productivity. Assessing the specific requirements of your project will help guide you toward the most suitable option.

Additionally, consider the features of the concrete pile breaking machine, such as its weight, mobility, and power source. A heavier machine might offer stability and durability for extensive work, but it could be less maneuverable on smaller job sites. Conversely, lighter machines can enhance mobility but may not deliver the same level of performance for tougher jobs. Furthermore, deciding between electric or diesel-powered machines can impact not only operational costs but also the machine’s efficiency in different environments.

Ultimately, the right choice of concrete pile cutting machine can significantly influence the overall success of your project. By carefully evaluating pile size, machine type, and key features, you can ensure that your equipment matches your project’s specific needs.

Investing time in this decision-making process will lead to better results, enhance productivity, and help avoid costly delays, ensuring that your construction timeline stays on track.

Act now! Get a professional quote for pile breakers and learn how to achieve a more efficient construction solution on your next project.