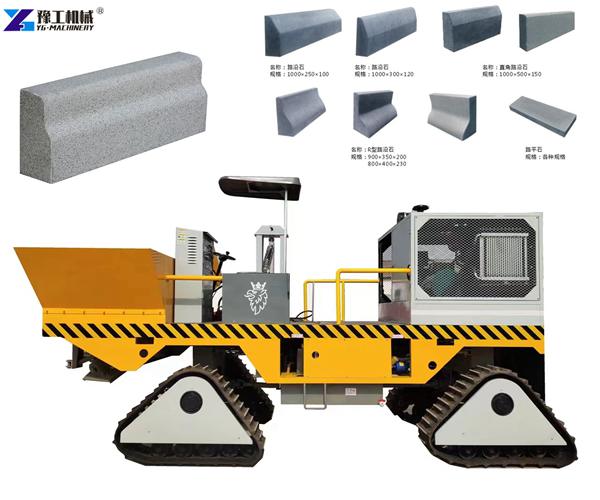

YG New design concrete curb and gutter machine exported to Cambodia.

This curb and gutter machine can produce road leveling stones, curb stones, and asphalt water strips. It is customized according to size.

The mold is replaceable. The automatic walking speed is fast, and the effect is good!!!

Parameters

| Model | YG-30 Multifonctional Fully Automatic Curb & Gutter Machine |

| Size | 5200*2400*2800mm |

| Construction scope | Width ≤ 2000mm (road shoulder, gutter), height ≤ 600mm (kerb, curb stone) |

| Weight | About 8000kg |

| Engine | 65kw, 380v, 4-cylinder turbodiesel engine |

| Forming method | High frequency vibrator (Applicable to plastic concrete) Formed shoulders and gutter have higher strength |

| Attached vibration motor (Applicable to dry hard concrete) Curb stones can be paved, and the height of the curb stones is higher. | |

| Automatic leveling system | Leveling range ±40mm |

| Steering Type | Dual automatic steering system |

| Minimum turning radius | 6800mm |

| Paving and transition speed | 1m-10m/min |

| Hopper volume | 1m³ |

| Walking drive form | Full-time four-wheel drive |

What are the curbs?

Curbs are marking stones placed between the road surface and other structures. Road Curbs are generally required between the separation strip and the road surface, and between the sidewalk and the road surface.

Curb Sape

There are several shapes of curb stones: vertical, inclined and curved.

Crawler type slipform concrete curb and gutter machine

This crawler-type curb stone slip forming machine is a new type of sliding mold machine. The walking drive is different. The crawler-type curb stone slip molding machine is mainly designed for sites where the ground flatness is not high. One of the characteristics of the crawler chassis is that the grounding ratio is low, which is conducive to equipment leveling.

How does the curb stone slip forming machine work?

The concrete curb and gutter machine can complete the entire process of curb stone laying in one go during on-site pouring construction, which can improve work efficiency and reduce labor intensity.

Plastic concrete can also be used as dry hard concrete. It is vibrated and compacted by a motor and then molded by a mold slip form. The Concrete Slipform Curb is vibrated and continuously formed while walking. The formed curb has high impact strength and stability, and its overall strength and stability It is unmatched by curb stones produced by traditional methods.

How to use the Concrete curb and gutter machine?

Using a concrete curb and gutter machine requires careful preparation and operation. Here is a step-by-step guide on how to use a concrete curb and gutter machine effectively:

- Preparations:

a. Ensure the work area is clean and free from debris.

b. Set up the necessary safety measures, including wearing personal protective equipment (PPE) such as goggles, gloves, and a hard hat.

c. Make sure the concrete mix is prepared according to the manufacturer’s instructions and is readily available. - Machine Setup:

a. Position the concrete curb and gutter machine at the starting point of the desired curb and gutter section.

b. Adjust the machine’s controls and settings according to the specifications of the project, including the desired curb height and width.

c. Securely anchor the machine to the ground to ensure stability during operation. - Concrete Placement:

a. Begin by pouring the prepared concrete mix into the machine’s hopper or conveyor system.

b. Activate the machine, allowing it to transport the concrete mix smoothly to the placement area.

c. Control the speed and flow rate of the concrete to ensure consistent and precise placement. - Shaping the Curb and Gutter:

a. Use the machine’s controls to shape the concrete into the desired curb and gutter profile.

b. Monitor the machine’s movement and adjust the controls as necessary to maintain the correct dimensions, smoothness, and alignment of the curb and gutter.

c. Pay attention to any additional features or attachments on the machine that may be used for specific curb and gutter details, such as drainage channels or flares. - Finishing:

a. Once the desired curb and gutter section is complete, ensure the concrete surface is smooth and free from imperfections.

b. Use hand tools, such as trowels, to refine the edges and finish the surface as needed.

c. Allow the concrete to cure according to the manufacturer’s recommendations before any additional work or traffic on the curb and gutter. - Cleaning and Maintenance:

a. After completing the curb and gutter section, clean the machine thoroughly to remove any residual concrete.

b. Follow the manufacturer’s instructions for maintenance and storage of the machine to ensure its longevity and optimal performance.

Curb & Gutter Paving Machines Factory

YG Machinery, as a certificated China Curb & Gutter Paving Machines Factory, provides kinds of high-quality paving equipment designed to streamline curb and gutter construction projects. 7/24 online services.

If you do not know how to select the right concrete curb and gutter machine for you projects, we are here to support you every step of the way. Contact us today to learn more.