How to break a huge rock into small pieces? Many demolition machines can be used for rock splitting and breaking. In the past mining and engineering construction processes, traditional blasting was the main mining method, which was extremely destructive. The accompanying huge shock waves, sky-wide dust and flying rocks have had a serious impact on the environment. The flying sand and rocks caused by the shock and vibration have caused great safety hazards to the surrounding living environment.

Therefore, more mining operations now adopt the following more environmentally friendly methods:

1.Hydraulic Rock Splitter

The hydraulic rock splitting machine is a portable tool designed for cutting rocks and demolish concrete inside buildings.

Working Principle

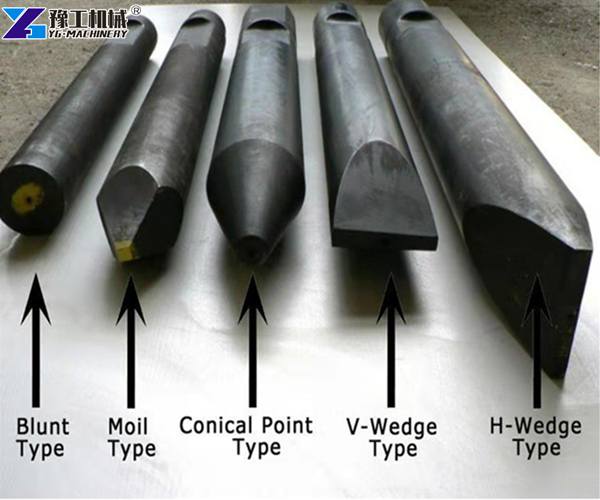

First, you should drill a specific straight and deep hole in the rock, then insert the machine wedge set (one middle wedge and two reverse wedges) into the hole, and the middle rock splitting wedge moves between the two reverse wedges through hydraulic pressure. The rock splitter moves forward and releases a huge amount of energy from the inside out, which will cause the object to split in a predetermined direction within a few seconds.

2.Excavator with rock splitting hammer

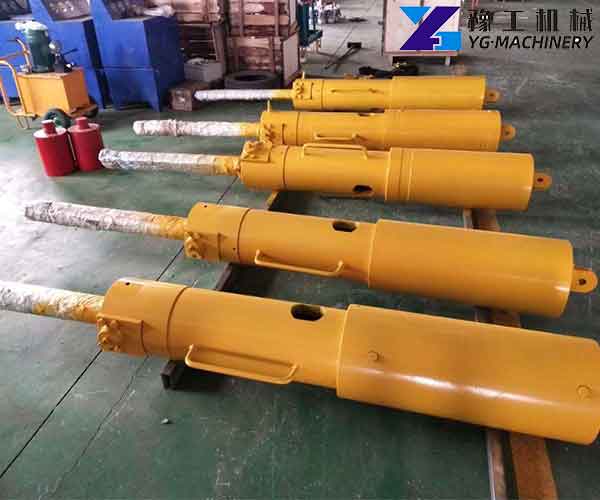

This rock splitter for excavator is a kind of atachement that is installed on the excavator, cranes or other carriers with hydraulics.

When destroying hard rock or high-strength reinforced concrete, the hammer head and lining plate are greatly worn, and a lot of metal materials are consumed. Frequent replacement of wear parts requires more repair time, which greatly reduces the cost and efficiency, and consumes production costs.

3.All-in-one Rock Drill and Splitter

The integrated rock drill and splitting machine is directly installed on the excavator. And drilling and splitting work can be performed in the cab. Drilling and splitting can be completed at one time, greatly improving work efficiency.

4.Hydraulic diamond wire saw machine

The diamond wire cutting machine is suitable for rock mining. Whether it is soft, medium or hard mines, or dry cutting of mine stones, etc., the wire saw machine can be cut at will. Mining stone with a cutting efficiency of up to 6-18㎡/h, completing the mining process at high speed, with a high yield rate, effectively saving mineral resources.

5.Cement expansion agent

First, drill holes are arranged in the rock, and then the expansion agent is inserted into the holes and sealed. After the expansion agent takes effect, the rock can be split.

Applications

Rock cutting and crushing: mining of granite, marble, bluestone, limestone, jade, iron ore, etc..

Tunnel and channel excavation, and rock crushing for other underground constructions.

Conclusions

How much is a rock spliting machine? The price ranges from thousands dollars to ten thousands dollars. Different machines for different projects. Which one is suitbale for your working environement? Please contact us to consult. We will provide best solutions to your rock splitting mining projects.