If you’re in the business of building from the ground up—literally—you know that everything starts with the soil. And when the soil isn’t behaving? You bring in the big guns. Or in this case, the YG Jet Grouting Drill Rig.

Technical Parameters of Jet Grouting Rig

| Model | YG-80A Jet Grouting Drill Rig |

| Max Torque | 3,500 N.m |

| Rotary Head Speed | 0–150 rpm |

| Max Feed Stroke | 3,500 mm |

| Rated Lifting Force | 30 kN |

| Allowed Feed Pressure | 35 kN |

| Drilling Depth | 60 m |

| Drill Pipe Diameter | Φ50 mm / Φ60 mm / Φ73 mm |

| Drilling Angle (Tilt) | 0–100° (forward & backward) |

| Motor Power | 30 kW + 18.5 kW + 1.5 kW |

| Dimensions (Working) | 3,700 × 2,050 × 6,600 mm (L×W×H) |

| Dimensions (Transport) | 5,600 × 2,050 × 2,100 mm (L×W×H) |

| Total Weight | 4,600 kg |

| Lateral Movement | 1,000 mm |

| System Pressure | 20 MPa |

| Max Climbing Gradient | 25° |

| Traveling Speed | 1 km/h |

YG Jet Grouting Equipment

Jet grouting is a ground improvement technique that involves injecting high-pressure grout (usually cement-based) directly into the soil. It fractures the surrounding material and mixes with it to form a soil-cement column that’s dense, durable, and ultra-stable.

Jet grouting is commonly used for:

- Foundation stabilization

- Excavation support

- Seepage control

- Settlement mitigation

- Underpinning existing structures

Real-World Example: Stabilizing a Subway Tunnel in Malaysia

A recent YG client in Kuala Lumpur faced severe soil instability while expanding the city’s subway line. Traditional piling methods weren’t cutting it. Enter the YG HFJG-6 rig. Within weeks, they had:

- Reinforced the tunnel entrance with over 120 grout columns.

- Reduced groundwater infiltration by 65%.

- Completed stabilization 2 weeks ahead of schedule.

The verdict? YG’s rig delivered deep strength in shallow time.

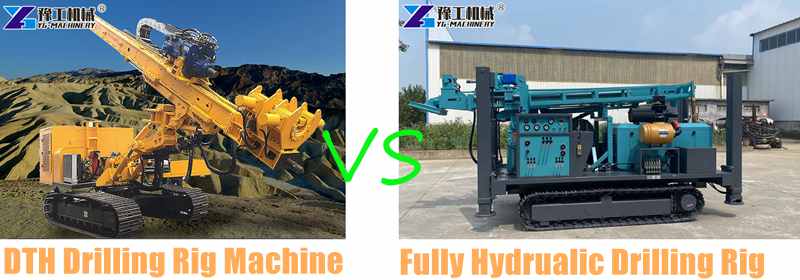

You may like also: Fully hydrualic core drilling rig for mining

FAQ: What You Need to Know Before You Buy

1. What are the key benefits of using a jet grouting drill rig?

Jet grouting offers precision, depth flexibility, and minimal disturbance to nearby structures—ideal for crowded cities or sensitive sites.

2. Can YG’s rigs handle different soil types?

Yes! YG rigs are designed to operate in clay, sand, gravel, silt, and even mixed soil conditions.

3. Do YG rigs comply with international standards?

Absolutely. YG Machinery can tailor machines to meet CE, ISO, or your country’s specific compliance standards.

4. How do I maintain a jet grout rig?

Regularly check grout pump systems, clean the nozzles, and inspect the rotary head for wear. YG provides a full maintenance manual and offers video support worldwide.

Shipping & Delivery: Yes, They Deliver Globally

YG Machinery ships to over 120+ countries and offers flexible delivery options—whether you need your rig shipped to a port in Houston or air-freighted to a project in Nairobi.

???? Pro tip: Bulk orders often come with discounts and accessories like extra nozzles or pipe sets.

???? Get a Free Quote in Minutes

Tell us what you need, and we’ll match you with the perfect jet grouting drill rig. Send your inquiry today — no commitment, just answers.