The hydraulic excavator rock breaker is suitable for 0.8 ton to 40 ton excavators.

Hydraulic breaker can also be installed on backhoe loader or wheel loader for crushing operation.

Larger working range and better operating vision.

Excavators are versatile and powerful machines used in construction, demolition, and mining operations. One key attachment that enhances an excavator’s capabilities is the hydraulic breaker. Hydraulic breakers, also known as demolition hammers or hydraulic hammers, are specialized tools that can be mounted on the arm of an excavator to provide high-impact demolition power.

Parameters of Excavator Rock Breaker

| Model | Unit | YGB100 | YGB200 | YGB300 | YGB400 | YGB600 | YGB800 | YGB900 | YGB1600 | YGB190 | YGB3500 |

| Weight | kg | 105 | 135 | 150 | 300 | 410 | 450 | 800 | 1600 | 1840 | 2800 |

| Length | mm | 900 | 1100 | 1200 | 1347 | 1528 | 1920 | 2260 | 2695 | 2810 | 3152 |

| Pressure | bar | 90-120 | 90-120 | 90-120 | 110-140 | 110-160 | 120-170 | 150-170 | 160-180 | 160-180 | 160-180 |

| Flow | lpm | 15-25 | 20-40 | 25-50 | 40-70 | 50-90 | 60-100 | 80-120 | 120-160 | 130-170 | 170-220 |

| Rate | bmp | 900-1400 | 700-1200 | 600-1100 | 500-900 | 500-800 | 400-700 | 400-700 | 400-700 | 400-600 | 250-400 |

| Hose | inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 1 | 1 | 1 |

| Chisel | mm | 40 | 45 | 53 | 68/70 | 75 | 85 | 100 | 135 | 140 | 155 |

| Suit | ton | 0.8-2.0 | 1.2-3 | 2.5-4.5 | 4-7 | 6-9 | 7-14 | 11-16 | 19-26 | 19-26 | 28-40 |

How Hydraulic Breakers Work

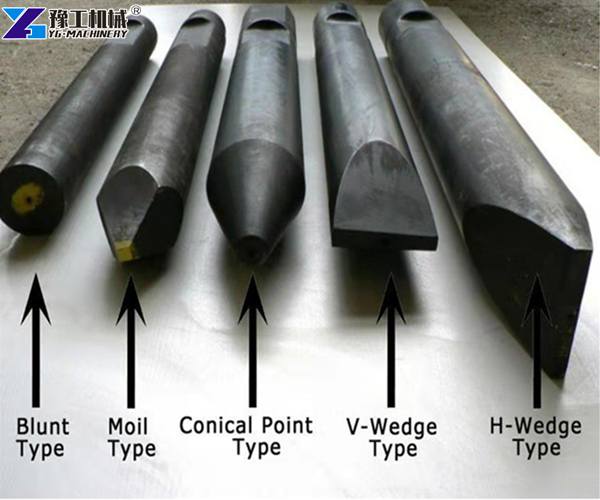

Hydraulic excavator rock breaker operate using the excavator’s hydraulic system. They consist of a heavy piston that is rapidly moved back and forth by hydraulic pressure and impacts a chisel or moil point tip. This repeated high-impact striking action allows the breaker to effectively crack, break, and demolish hard materials such as concrete, rock, and asphalt.

The hydraulic fluid from the excavator’s hydraulic system powers a hydraulic cylinder inside the breaker. This cylinder moves the piston back and forth, creating the powerful impact blows. The frequency and force of the blows can be controlled by adjusting the hydraulic flow and pressure.

Benefits of Using Hydraulic Breakers

Hydraulic breakers provide several key advantages when used with excavators:

- Increased Demolition Power: The rapid, high-impact blows of a hydraulic breaker allow it to efficiently break apart tough materials that would be difficult to demolish with the excavator’s arm alone.

- Selective Demolition: Excavator rock breaker enables precise, targeted demolition, allowing operators to selectively demolish specific structures or materials without damaging surrounding areas.

- Versatility: Breakers come in a range of sizes and can be matched to different excavator models, providing flexibility for a variety of demolition and site preparation applications.

- Improved Productivity: Hydraulic breakers can significantly increase the speed and efficiency of demolition and site clearing work compared to manual methods or using the excavator’s arm alone.

- Reduced Physical Strain: Operating a hydraulic excavator rock breaker requires less physical effort from the excavator operator compared to manual demolition tools.

Choosing the Right Hydraulic Breaker

When selecting a hydraulic breaker for an excavator, it’s important to choose one that is properly sized and matched to the specific excavator model. Factors to consider include the excavator’s operating weight, hydraulic flow and pressure capabilities, and the required demolition power for the job at hand. Working with a reputable equipment supplier can help ensure the right breaker is selected for optimal performance and safety.

Overall, hydraulic breakers are a valuable attachment that can significantly enhance an excavator’s demolition and site preparation capabilities. By providing high-impact power and precision, they help construction and mining operations work more efficiently and effectively.