The steel pipe thread rolling machine is a mechanical equipment specially used for steel pipe thread processing. It is widely used in construction, petroleum, chemical industry, machinery manufacturing and other industries.

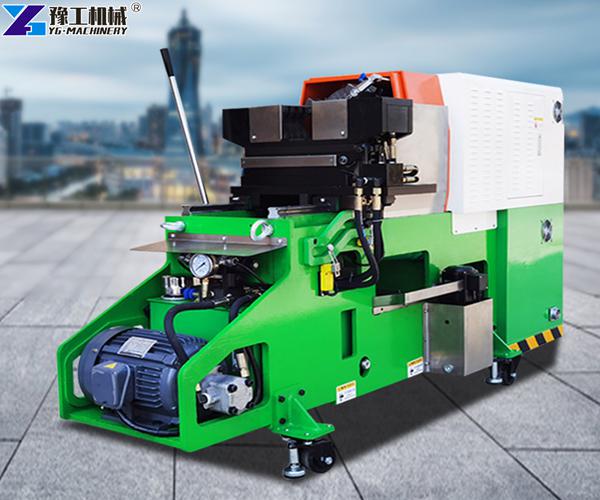

Stainless steel pipe threader for sale at good price

The steel pipe threading machine is mainly used to process the external threads of steel pipes, so that different steel pipes can be connected through threads to form a closed piping system.

Technical Parameters of pipe thread rolling machine

| Power Supply Method | Three phase AC 380V 50HZ |

| Rated power | 8.6KW |

| Equipment weight | 870KG |

| Machine range | 4/8-4inch |

| Spindle speed | High, medium, and low gears 126/87/48 rpm |

| Maximum working hydraulic pressure | 12Mpa |

| Maximum holding force | 110kg |

| Dimensions | 1800*600*1100mm |

Don’t miss out! Inquire now to enjoy a limited time discount and increase your processing capabilities!

Main applications of metal pipe threading machine

Pipeline connection: It can process the external threads of steel pipes, so that different steel pipes can be connected through threads to form a closed pipeline system, which is used in construction, water supply, gas supply and other industries.

Elevator manufacturing: The pipe thread rolling machine can process elevator guide rails, cars, door systems and other components, playing an important role in elevator manufacturing.

Engineering machinery: The pipe thread rolling machine can also be used for parts processing in engineering machinery, automobiles, electronic appliances, CNC machine tools and other fields.

Working principle of threading machine

- Put the steel pipe to be processed into the pipe chuck and hit it to clamp it.

- Adjust the size of the die opening on the die head and set the thread length.

- Turn the feed handwheel clockwise to make the die cutter on the die head close to the end of the rolling pipe with constant force.

- The die cutter automatically cuts the thread, and the cooling system sprays oil for cooling.

- When the preset length is processed, the die cutter automatically opens and the thread processing is completed.

- Turn off the power, hit the chuck, and take out the processed pipe.

Advantages of stainless steel pipe threading machine

With its intelligent and automated features, the pipe thread rolling machine greatly improves the processing accuracy and speed.

One-button switch of pipe diameter, setting of thread length and depth,

Easy and efficient operation, stable and durable quality.

Automatically complete threading, reduce manual operations and improve work efficiency.

This metal pipe threading machine is applicable to steel pipes of various diameters, thicknesses and materials to meet the needs of different industries.

Buy here stainless steel pipe threader

The pipe thread rolling machine can adjust processing parameters according to different needs, adapt to the processing of steel pipes of various specifications, and meet the needs of different customers.

We provide comprehensive after-sales services, including equipment maintenance, technical support and operation training, to ensure that users can use the equipment smoothly.

About Us

YG Machinery, also named Henan Yugong Machinery, is a professional rebar processing machinery manufacturer and supplier from China. We provide kinds of rebar machinery, such as CNC rebar bending machine, steel bar cutting machine, rebar threading machine, etc.

Want a customized threading machine solution? Contact us for a professional quote and advice!