The crawler-type multi-functional water well drilling rig is a new, efficient, energy-saving and multi-functional hydraulic deep well drilling machine. Deep well drilling machine is mainly used for drilling water wells, monitoring wells, geothermal air conditioning holes, anchoring, foundation and bridge pile holes, etc.

Deep Well Drilling Machine Specifications

| Model | YG-300 | YG-400 | YG-800 |

| Power | 70kw | 95kw | 194kW |

| The hole diameter | 140-305mm | 140-350mm | 140-400 mm |

| Drilling depth | 300m | 400m | 800m |

| Drill pipe diameter | φ102mm φ108mm φ114mm | φ102mm φ108mm φ114mm | φ102mm φ108mm φ114mm φ117mm |

| Drill pipe length | 1.5m 2.0m 3.0m | 1.5m 2.0m 3.0m | 1.5m 2.0m 3.0m 6.0m |

| Rig lifting force | 6.6 ton | 24 Ton | 36 Ton |

| Walking speed | 2.5km/h | 2.5 km/h | 2.5 km/h |

| Climbing angles(Max.) | 30° | 30° | 30° |

| Dimensions(mm) | 5900*1750*2450mm | 5200*2000*2780mm | 6300*2300*2650 mm |

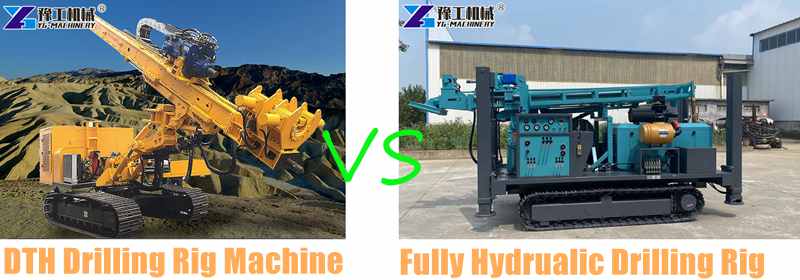

The drilling rig uses a variety of construction technologies such as down-the-hole hammer impact, mud drilling, reverse circulation drilling, casing follow-up and protective wall drilling, etc., which effectively solves construction drilling problems in various terrains.

A water well digging equipment is composed of power equipment and drill bits, drill pipes, core pipes, drill frames, etc.

Equipped with an imported optional high-torque hydraulic rotating power head, which can be selected according to different construction requirements, greatly saving equipment purchase costs and effectively improving construction efficiency.

The loose layer can be drilled with a drill bit, sludge discharged, reverse circulation construction, etc.

The rig’s hydraulic support legs have a large stroke and can be transferred and loaded without the need for a crane.

How to choose the water well drilling rig?

- Drilling depth and diameter: Based on actual needs, determine the required drilling depth and diameter, and select a drilling rig configuration that can meet these needs.

- Power source: Diesel engine drilling rigs have greater power and stronger torque and are suitable for drilling operations with larger diameters and depths; while electric motor drilling rigs are more suitable for small-diameter shallow well operations.

- Drilling rig type: For example, for hard rock layers, you need to choose a drilling rig with greater impact and cutting force; while for soft soil layers, you can choose a rotary cutting drill.

- Auxiliary equipment: If needed, you can also buy mud pumps, water pumps, etc. These equipment can provide necessary circulating fluid, coolant, etc. for drilling operations to ensure the normal operation and drilling efficiency of the drilling rig.

- Safety: The drilling rig should be equipped with some safety features, such as explosion-proof, fire-proof and other measures. During the drilling process, attention needs to be paid to preventing accidents such as gas explosions and fires, and a drilling rig configuration with safety guarantees must be selected.

- Operation convenience: It’s better to hoose a drilling rig configuration with a high degree of automation, simple operation, and easy maintenance. This can improve drilling efficiency, reduce manual operating errors, and reduce failure rates.

- Economics: You should choose a cost-effective drilling rig configuration to avoid unnecessary waste. Feel free to contact us to get the drilling machine price.

How to choose drill bits for different rock formations?

The drill bit is one of the important drilling tools in water well drilling. Without the drill bit, the water well drilling rig equipment cannot work normally. This shows the importance of the drill bit in the water well drilling rig. For different types of water well drilling equipment, different drill bits are required in production. When selecting drill bits for water well drilling equipment, you should pay attention to the following aspects:

- When drilling in soft rock with better drillability, the drilling speed is faster, so you need to choose one with larger slag discharge volume and higher slag discharge quality. It is best to choose a Four wing PDC concave drill Bit.

- When drilling in hard rock, due to the high strength of the rock, each column tooth and drill bit need to bear a large amount of load, so it is necessary to choose a drill bit with higher strength for the drill bit body and column teeth.

- When drilling rocks containing clay, because the clay is relatively loose, the slag discharge holes are often blocked, so you can choose a Mud Rotary Bit (Side Discharge).

- When drilling in rocks with relatively good toughness, you can choose a wedge-shaped tooth drill bit to ensure safe production.

400 meters Water well drilling equipment for sale in Mexico

Isaac Torres, ceo of well drilling company from Mexico, ordered YG-400 water well borewell drilling machine.

Drilling depth: 400 meters

600 meters Water well drilling rigs for sale in Senegal

Moustapha Dieye, a CEO of importe trading company from Senegal, bought a crawler water well drilling rig for his client.

Drilling depth: 600 meters.

High efficiency and multifunctional hydraulic deep well drilling machine is mainly used for drilling water wells, monitoring wells, precipitation wells, rescue wells, gas layer mining, and other exploration projects.

800 meters Water well drilling truck for sale in USA

Mr. Sampson from America ordered one set of 800m water well drilling rig machine from YG Machinery.

300 metes Water well drilling equipment for sale in Honduras

Ricardo purchased 300m water well drilling rig with a air compressor from YG Machinery.

Drilling Depth: 300 meters

This air rotary well drilling machine is powerful outil. It is easy to load and unload on truck. This machine can drill holes in different strata (rock layer, mud layer, sand layer).