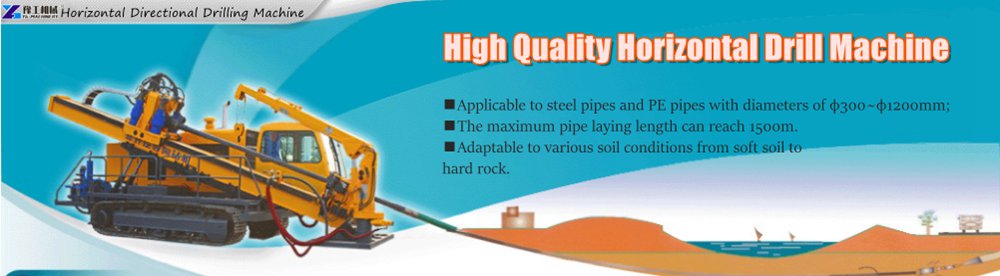

Horizontal directional drilling machinem also named HDD Machine, is a construction machine that lays various underground utilities (pipelines, cables, etc.) without excavating the surface of the ground.

Horizontal directional drilling technology has been widely used in various industries such as communications, electricity, water conservancy, gas, municipal administration, etc. It has shown unique advantages in environmental protection and municipal pipe network expansion projects and large-scale pipeline crossing river projects.

Choose the HDD Machine Model for your project

YG Machinery provides types of directional drilling machine for sale.

| Model | YG-160A | YG-180 | YG-280 | YG-320 | YG-320A |

| Engine rated power | 100KW | 97KW | 160KW | 140KW/160KW | 160KW |

| Push and pull | Cylinder | Motor | Motor | Cylinder | Motor |

| Maximum reaming hole diameter | Φ600mm | Φ600mm | Φ750mm | Φ800mm | Φ800mm |

| Drill rod length (single) | 3m | 3m | 3m | 3m | 3m |

| Drill pipe diameter | Φ60mm | Φ60mm | Φ73mm | Φ73mm | Φ73mm |

| Drill angle | 10-23° | 10-22° | 10-23° | 10-20° | 10-20° |

| Maximum mud flow | 160L/min | 250L/min | 320L/min | 320L/min | 320L/min |

| Maximum mud pressure | 100bar | 80bar | 80bar | 80bar | 80bar |

| Overall quality | 6700kg | 8500kg | 12500kg | 11500kg | 11200kg |

| Dimensions | 5.7*1.82*2.4m | 6.4*2.27*2.34m | 7.1*2.26*2450m | 7.1*2.25*2.45m | 7.662*2.162*2.45m |

Horizontal Drill Machine for sale in Indonesia

- Steel belt with rubber plate

- Three-speed adjustable push-pull speed (high, medium, low)

- Girder sliding luffing mechanism

- Optional panoramic rotating cab or operating platform

- Power head with reserved boost

- Optional automatic rod feeding mechanism, automatic hydraulic staggering

The HDD Machine is composed of drilling rig system, power system, direction control system, mud system, drilling tools and auxiliary equipment.

YG Machinery, as a reliable HDD Machine Drilling Rig manufacturer, has more than 19 years of experience in trenchless construction. The horizontal directional drilling, directional boring drilling equipment, and trenchless drilling rigs produced by our company have gained a good reputation in the market. And the after-sales service is guaranteed. Welcome to call for consultation and negotiation of HDD Machine!

Our Services

We also provide Accessories

Drill Bits and Reamers

Various types and sizes of drill bits and reamers are available to match specific soil conditions and project requirements. They ensure efficient penetration and hole enlargement during the drilling process.

Explore Features

Locating Equipment

Specialized locating equipment, such as electronic trackers and sonde transmitters, helps operators precisely track the location of the drilling head and guide its path accurately.

Contact Sales

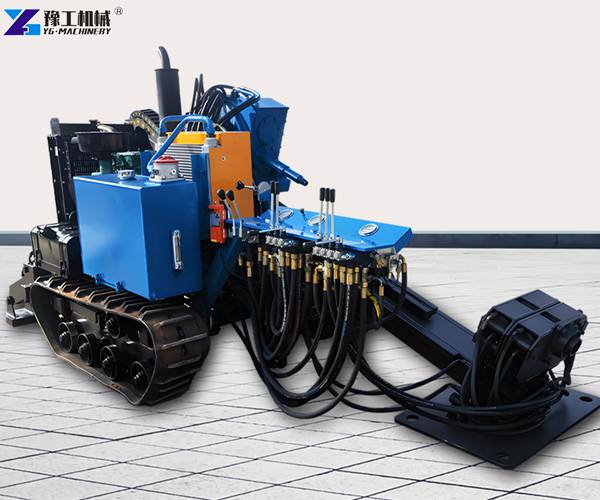

Directional Boring Machines for sale in Saudi Arabia

- Integrated design

- Self-propelled rubber tracks

- Small body meets the needs of construction in narrow sites

- Equipped with drill rod box

Contact our expert to get the HDD Machine price in Saudi Arabia.

YG-160 HDD Machine Price in America

- Engine: 4102 engine 55 kW

- Maximum push and pull force: 135N.M

- Moving mode: remote control, crawler, 2 km/h

- Injection system: 160 type three-cylinder mud pump mud pump

- Maximum pressure: 2.8

- Entry angle: 28°

- Departure angle: 20°

- Drill rod diameter: 50 (mm)

- Drill rod length: 2 (m)

Check here the working case of hdd drilling machine for sale in the USA.

How does the Horizontal Drill Machine work?

We simply divide the construction into three processes:

- Before construction

- During construction

- After construction

Before construction

It is necessary to do a good job of investigation, design, and understanding of the underground pipeline network. Timely communicate with the original pipeline property unit to understand the original pipeline route and copy relevant drawings. At the same time, understand the terrain, underground rivers, geographical changes and other matters with the local government and residents. If necessary, you can arrange for a geological survey.

During construction

The on-site construction can be divided into 10 steps:

- Fixed point reset: confirm the point according to the design drawings.

- Safety guidance: it is necessary to set up safety fences in the construction area to guide the surrounding residents and vehicles to take detours to ensure the orderly development of safety production work.

- Equipment erection: the HDD machine goes to the predetermined location and stabilizes the platform.

- Material preparation: the drill stem and related instruments and equipment materials, generators, water pipes, bentonite and other materials are ready.

- Directional crossing: start the crossing operation.

- Hole expansion and re-crossing: after the crossing is completed, expand the hole and cross again.

- Pipe material preparation: prepare the pipe material according to the actual crossing length, pipe diameter and number of pipes.

- Pipeline backhaul: lay the pipe material.

- Cleaning and protection: clean the construction site, protect the pipe hole and do the corresponding plugging and backfilling protection work.

- Well setting and connection: according to the properties of the pipeline network, after the well pit is excavated, connection, well making, and inspection valve setting are carried out. Generally speaking, there is a certain period of interval between well setting and the first 9 steps.

After Construction – Final Checks and Cleanup

- Inspection: Once the pipe has been successfully installed, it undergoes pressure testing to ensure there are no leaks. Visual inspections are also conducted to verify proper placement.

- Site Restoration: The area is cleaned up, and any surface disruption caused by the drilling process is restored to its original condition.