The GRC / GFRC pump and spray station is the most important equipment in GRC production. GRC Spray Machine mainly consists of a material hopper, a control pannel, a rotary transportation pump and a spray gun.

It can spray 200-600㎡ per hour.

Parameters of GRC Spray Machine

| Model | YG-Y80 GRC shotcrete machine (screw type) | YG-Y100 GRC Spray machine (plunger type) |

| Power supply | 380V 50HZ (three-phase) | 380V 50HZ (three-phase) |

| Production efficiency | 300-400㎡/h | 300-600㎡/h |

| Working air pressure | 0.6-0.8mpa | 0.6-0.8mpa |

| Capacity | 50L | 60L |

| Conveying capacity | 300-1600kg/h | 300-1600kg/h |

| Working area | 4.0 meters (horizontal arm radius) | 4.5 meters (horizontal arm radius) |

| Speed | 40-200r/min | 20-280r/min |

| Power | 2.2-3.0KW stepless speed regulating motor | 1.5-2.2KW stepless speed regulating motor |

| Dimension | 1400*1000*2200mm | 1300*1000*2200mm |

| Equipment weight | 220kg | 300kg |

What is the GRC Spray Machine used for?

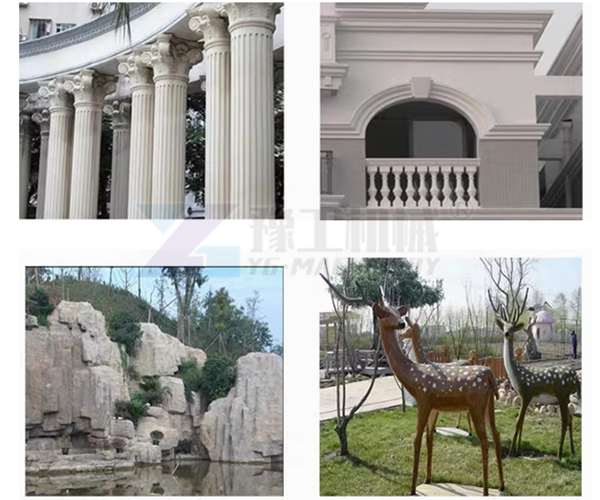

The GRC GFRC spray machine is mainly used for spraying kinds of GRC European components (cement mortar mixed with glass fiber chopped wire combined spraying), spraying indoor and outdoor wall decoration (putty powder, latex paint, real stone paint, etc.), spraying fireproof and waterproof material, spraying insulation material, relief crafts paint, and small villas , clubs, bridges, rockeries, dams, river embankment guardrails, etc.

Main products of GRC Spray Machine: GRC board, GRC component, European line board, European cement component, GRC eaves line | waist line, GRC Roman column, GRC vase column, GRC lightweight partition board, European building component GRC rockery, GRC fireplace, GRC grape trellis, GRC joists, GRC paneling, GRC curtain wall, GRC cement lines, GRC wall panels.

Features of GRC Machine

- Compact structure, small size, easy to disassemble and maintain.

- Low level material hopper, ease to load.

- The high speed mixer can be used for mixing GRC mortar, as well as ordinary cement mortar, ultra-fine cement mortar, EPS, GRC, real stone paint, coatings and other materials.

- GRC glass fiber spraying machine is equipped with Concentric Spray Gun which can do fan spraying or directional spraying.

- The GRC spray pump feeds materials evenly without obvious pulses.

You may also need: Concrete spraying machine for sale.

How to use the GRC/GFRC pump spray station?

Step 1. You should prepare all ingredients and raw materials in proportion.

Step 2. Pour the raw materials into the mixer for mixing. After the mixing, you can pour the mixed cement slurry into the hopper.

Step 3. The screw pump rotor is driven by the reducer and rotates to squeeze out the cement slurry and transport it to the spray gun through the plastic pipe.

Step 4. Spray the cement slurry into the mold with a spray gun. Just wait to demould when it is dried naturally.

Comparative introduction to the advantages of GRC products and Marble

- GRC is a green, environmentally friendly and renewable product recognized by the international community. The use of GRC is more common than marble. We can definitely do complex shapes of GRC products that marble cannot do.

- Marble modeling costs are high and the production cycle is long.

- The color of marble is monotonous, and it depends on the original color of the stone. While we can adjust the GRC product color according to customer requirements.

- The service life of GRC products is more than 70 years.

- As for the raw material components, marble is a type of rock. GRC is composed of quartz sand, exported glass fiber, reinforcing agent and many other materials. It is sprayed layer by layer by a high-pressure GRC spray machine. The glass fibers are evenly and cross-wound in the concrete, giving the product features such as high density, high strength, and tensile resistance.

Why the GRC products are popular?

By adjusting the mold, GRC can make complex shapes. The production cycle is short, the price is lower than other materials, the weight is lighter than marble, the strength is high, the bending resistance, compression resistance, impact resistance are higher than marble, and it is resistant to high temperatures and weathering.

GRC products shapes: oversized eaves, sculptures, spires, handrails, vases, Roman columns and other shapes.

Conclusion

The GRC Spray Machine offered by YG Machinery has been approved by users from all over the world. YG Machinery, as a reliable partner for construction professionals seeking top-quality machinery solutions, provides kinds of machines used in the construction industry. Hot selling machines: concrete pump trailer, concrete pile breaker, concrete wire saw machine, excavators and attachments, etc.

Why construction companies should choose YG Machinery’s GRC Spray Machine? With our GRC/GFRC spray machine, you can enhance your productivity, achieve superior project outcomes, and stay ahead in the ever-evolving construction landscape.

What are you waiting for? Contact us today to get the GRC machine for sale price.