Looking to step up your metalworking game? Our CNC plasma cutter for sale will take your projects to the next level. With precision cutting capabilities and advanced technology, this machine is perfect for hobbyists and professionals alike.

Say goodbye to manual cutting and hello to effortless precision with our CNC plasma cutter for sale. Don’t miss out on this opportunity to enhance your workshop – get your very own CNC plasma cutter today!

You may also like: Metal punching and shearing machine for sale

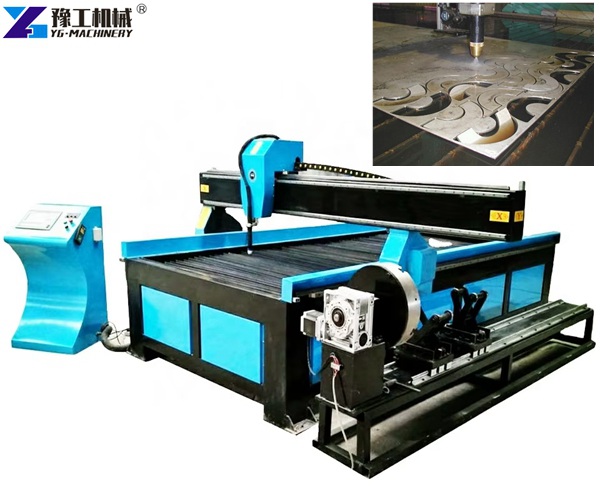

CNC Metal Plasma Cutting Machine for Sale

CNC plasma metal cutting machine is a highly efficient automated cutting equipment widely used in the metal processing industry. It uses computer numerical control (CNC) technology to control the plasma cutting torch to move along a predetermined path to achieve precise cutting of various metal materials.

Technical parameters of cnc plasma cutter for sale

| X,Y-Axis Travel | 1300*2500 ,1500*3000, 2000*3000mm |

| Repeatability | +/- 0.05mm |

| Max. Rapid Travel Speed | 30m/min |

| Drive System X and Y axis | Rack and Pinion, rail linear bearing |

| Motor | Stepper/Servo |

| Working Voltage | AC380V/50HZ, 3PH; 220V/60Hz,3PH; AC440V/50HZ, 3PH |

| Command Language | G Code |

| Plasma Power Supply | 60A, 100A, 120A, 200A i.e. |

| Operating System | Start Shaphon & Torch Height Controller |

Are you looking for a CNC plasma cutter for sale? Look no further! Leave your messages by clicking the button and get the factory price.

Operating Mechanism

The CNC plasma cutter for sale operates by utilizing the intense heat generated by a high-temperature plasma arc to melt and vaporize the metal at the cutting edge of the workpiece. Concurrently, a high-velocity airflow expels the molten metal, creating a clean incision. The entire process is meticulously regulated by the CNC system to guarantee optimal cutting quality and efficiency.

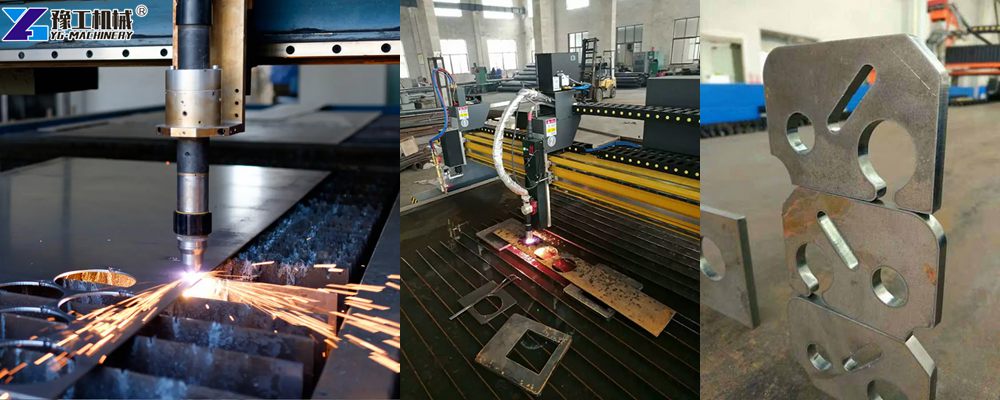

Industrial Gantry Plasma Cutting Machine

The gantry CNC plasma cutting machine is the preferred option for cutting different specially shaped carbon steel types such as Q235B, Q345B, and S45C/S50C hot-rolled wide and thick plates, as well as metal sheets. This CNC cutting machine is capable of producing various shapes and features functions like automatic nesting, height adjustment, ignition, flameout, and a one-key switch between flame and plasma cutting. It is user-friendly and does not necessitate advanced knowledge or technical skills. If you are familiar with CAD software, you can quickly learn to operate it in just one hour.

Technical informations of gantry type cnc plasma cutting machine

| Track gauge | 3000-10000mm | |

| Effective cutting width | 2300-9300mm | |

| Effective cutting length | Track length minus 2500mm | |

| Minimum torch spacing | CNC | 200mm |

| Straight bar | 80mm | |

| Cutting thickness | 6-100mm | |

| Cutting speed | 50-1000mm/min | |

| Idle speed | ≤6000mm/min | |

Gantry plasma cutting machine VS CNC plasma table for sale

Below are the comparaisons between the Gantry plasma cutting machines and cnc plasma cutting table for sale:

Cutting Capacity

- Thickness: Gantry plasma cutting machines can handle thicker metal materials, effectively cutting steel plates over 20mm thick, while cnc plasma table is generally limited to 20mm or less.

- Speed: Thanks to their design and power systems, gantry plasma cutting machines can maintain high cutting speeds over large areas, making them ideal for batch production.

Precision and Quality

- Accuracy: Gantry plasma cutting machines deliver superior cutting accuracy, particularly for intricate shapes and details, making them suitable for high-quality cutting applications.

- Thermal Deformation Control: The gantry design minimizes the heat-affected zone, reducing the risk of material deformation, which is crucial when cutting large areas.

Equipment Stability

- Structural Stability: Gantry plasma cutting machines feature a more robust structure that can endure greater loads and vibrations, making them suitable for long-term continuous operation, whereas sheet metal plasma cutting tables may lack this level of stability.

- Duty Cycle: Gantry machines typically have a higher duty cycle, allowing for longer and more efficient operation, while cnc cutting table for sale often operates intermittently.

Application

Gantry plasma cutting machines can process a wide range of metal materials and are extensively used in heavy industry, construction, shipbuilding, and other sectors, whereas cnc metal cutting table is more suited for small-scale processing or educational purposes.

How Much Does a CNC Plasma Cutter Cost?

Do you want to buy the CNC plasma cutter for sale? Feel free to ask our expert to get the cnc plasma cutter price.

China Factory – CNC Plasma Cutter for Sheet Metal Manufacturing

Our technical R&D team consists of 50 professionals. Our products are distributed nationwide and exported to Europe, America, Southeast Asia, and the Middle East. With 20 years of innovation in research and development, we have secured numerous domestic technical patents. We have established a leading R&D platform for welding and cutting within the industry, and our core technology has earned over 50 authorized invention patents and software copyrights.

We prioritize customer satisfaction and maintain high-quality standards throughout our procurement and production processes. Our facilities are equipped with advanced production and processing machinery, including numerous high-precision CNC machining centers, laser cutting machines, and automated production lines for precise manufacturing.

Our robust after-sales team provides comprehensive customer service support. We have over 30 dedicated after-sales professionals who respond actively 24/7, offer free on-site equipment installation and operational training, provide free repairs and maintenance for one year (excluding wear parts), and deliver lifelong technical support.