Automatic stirrup bending machine is essential tool in the construction industry, designed to enhance efficiency and precision in the processing of reinforcement bars (rebar). The machine automates the bending and cutting of steel stirrups, which are critical components used in concrete structures for added strength and stability.

Technical Parameters

| Model | YG-1 | YG-2 |

| Single wire | Round steel 4-10mm Deformed steel bar 4-8mm | Round steel 4-12mm Deformed steel bar 4-10mm |

| Double wire | Round steel 4-6mm Deformed steel bar 4-6mm | Round steel 4-8mm Deformed steel bar4-8mm |

| Max bending angle | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min |

| Maximum bending speed | 800°/sec | 800°/sec |

| Machine size | 2600*800*1700mm | 3280*1000*1700mm |

| Pieces Processed | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa |

| Total Power | 14kw | 20kw |

| Working temperature | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° |

| Average power | 4.5KW/h | 5KW/h |

| Total weight | 1150KG | 1350KG |

The automatic stirrup bender is mainly used for bending hooks and hoops of cold-rolled ribbed steel bars, hot-rolled grade 3 steel bars, cold-rolled round steel bars and hot-rolled round steel bars in construction.

Features of CNC Stirrup Bending Machine

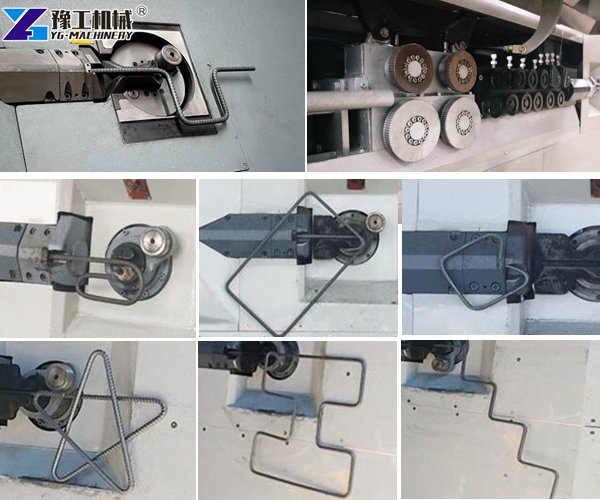

- The machine automates the entire process of bending, cutting, and shaping steel bars, significantly reducing manual labor and increasing productivity.

- It is operated by 1-2 people, light and flexible, and 3-5 times faster than manual bending.

- The use of computer numerical control (CNC) allows for precise programming and execution of various bending shapes and angles, enhancing accuracy in production.

- It can store multiple bending programs facilitates easy switching between different tasks without reprogramming.

- CNC stirrup benders can handle various wire diameters (typically ranging from 4 mm to 12 mm) and can perform both single and double rib bending configurations.

- Automatic Stirrup Bender Machine can achieve up to 1050 bends per hour for single rib configurations, significantly boosting output while maintaining precision.

How to Choose the Right Automatic Stirrup Bending Machine for Your Project

Choosing the right Automatic Stirrup Bending Machine for your project can significantly impact both efficiency and output quality. With a multitude of options available on the market, understanding your specific requirements is crucial. To start, consider the volume of production you anticipate. If your project entails high output, then investing in a more advanced machine with greater bending capacity and speed may be necessary. Take note of the machine’s specifications, including its bending angles and the size of stirrups it can produce, as these will directly influence its suitability for your needs.

Next, evaluate the automation features that different machines offer. An Automatic Stirrup Bending Machine with advanced controls can enhance precision, reduce manual effort, and minimize the likelihood of errors during production. Look for machines that offer programmable settings, allowing operators to easily adjust parameters for various tasks. Additionally, consider the machine’s ease of operation and maintenance; a user-friendly interface not only streamlines training for your staff but also reduces downtime for repairs, thus maximizing productivity.

It’s also essential to assess the durability and quality of the machine itself. A well-constructed Automatic Stirrup Making Machine made from high-quality materials will withstand the rigors of continuous use and the demands of a busy work environment. Researching brands and models that are known for reliability can save you from potential headaches down the road. Always read customer reviews and seek recommendations from industry professionals to gain insight into how different machines perform in real-life applications.

Finally, budget considerations cannot be overlooked. While it’s tempting to opt for the cheapest option available, investing in a higher-quality Automatic Stirrup Bending Machine can yield better long-term value.

Look for features that justify the cost, such as energy efficiency, support services, and warranty plans. Ultimately, the right machine should align with your project requirements, operational capacity, and budgetary constraints, setting you up for success in your next endeavor.

YG Machinery

YG Machinery offers types of rebar machinery, such as Barbed Wire Machine, metal plate rolling machine, rebar straightening and cutting machine, thread rolling machine, rebar bending machine, metal punching shearing machine, etc.