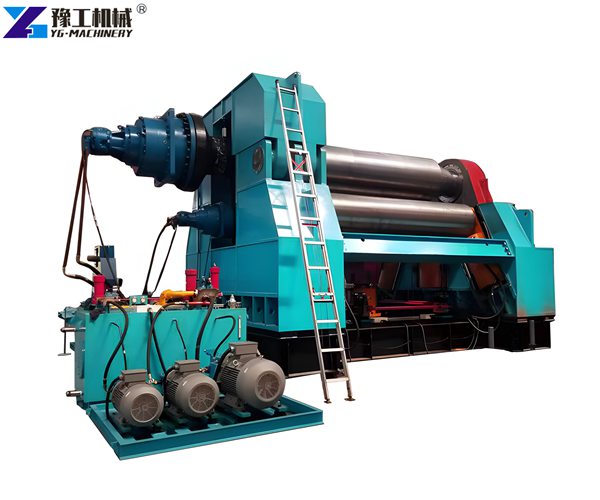

Imagine transforming a flat, rigid steel plate into a perfectly curved cylinder or cone. Sounds like magic, right? Well, it’s not magic—it’s the power of a steel plate rolling machine. This guide will walk you through everything you need to know about hydraulic plate bending machine. From how they operate to the different types available, we’ve got you covered. Let’s roll into it!

YG Steel Plate Rolling Machine For Sale

The hydraulic plate bending machine is a heavy-duty piece of equipment designed to bend and shape metal plates into curves, cylinders, or cones. Think of it as a giant rolling pin for steel, but with way more precision and power. These machines are essential for creating everything from pipelines to wind turbines.

Technical Parameters of Hydraulic Plate Bending Machine

| Model | Working Length (mm) | Max. Thickness (mm) | Pre- Bending (mm) | Upper (Φmm) | Under (Φmm) | Side (Φmm) | Motor Power (km) | dimension(cm) |

| W12S-4×2000 | 2000 | 4 | 3 | 160 | 140 | 120 | 2.2 | 392x86x114 |

| W12S-4×2500 | 2500 | 4 | 3 | 190 | 170 | 150 | 3 | 402x125x138 |

| W12S-4×3200 | 3200 | 4 | 3 | 210 | 190 | 170 | 7.5 | 466x132x137 |

| W12S-4×4000 | 4000 | 4 | 3 | 270 | 250 | 210 | 5.5 | 600x143x152 |

| W12S-6×2000 | 2000 | 6 | 4 | 190 | 170 | 150 | 3 | 402x125x138 |

| W12S-6×2500 | 2500 | 6 | 4 | 210 | 190 | 170 | 7.5 | 466x132x137 |

| W12S-8×2000 | 2000 | 8 | 6 | 210 | 190 | 170 | 7.5 | 416x132x137 |

How Does It Work?

The process is surprisingly straightforward:

- The steel plate is fed into the machine.

- Three or four rollers apply pressure, gradually bending the plate into the desired shape.

- The operator adjusts the rollers to achieve the perfect curvature.

It’s like baking a perfect croissant—precision and control are key.

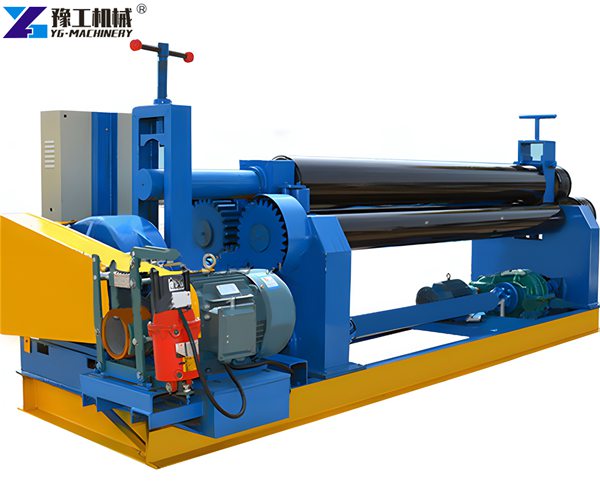

Types of Steel Plate Rolling Machines

Not all rolling machines are created equal. Here’s a breakdown of the most common types:

| Type | Description | Best For |

|---|---|---|

| 3-Roller Plate Roll | Uses three rollers to bend the plate. Simple and cost-effective. | Light to medium-duty tasks. |

| 4-Roller Plate Roll | Adds an extra roller for better precision and control. | Heavy-duty industrial applications. |

| Variable Geometry | Allows for adjustable roller positions, offering maximum flexibility. | Complex shapes and custom projects. |

Read also: Steel bar bending machine for sale

Applications of Steel Plate Rolling Machine

These machines are everywhere—literally. Here are some industries that rely on them:

- Construction: Creating curved beams, arches, and tanks.

- Shipbuilding: Shaping hulls and other structural components.

- Aerospace: Crafting precision parts for aircraft.

- Energy: Producing wind turbine towers and pipelines.

Without steel plate rolling machines, modern infrastructure as we know it wouldn’t exist.

Frequently Asked Questions (FAQs)

1. What’s the difference between a 3-roller and 4-roller machine?

A 3-roller hydraulic plate bending machine is simpler and more affordable, making it ideal for smaller projects. A 4-roller machine, on the other hand, offers greater precision and is better suited for heavy-duty tasks.

2. Can a steel plate rolling machine handle other metals?

Absolutely! While they’re designed for steel, many machines can also roll aluminum, copper, and even titanium. Just make sure to check the machine’s specifications.

3. How do I maintain a steel plate rolling machine?

Regular maintenance is key. Keep the plate rollers clean, lubricate moving parts, and inspect for wear and tear. A well-maintained machine can last decades.

4. What’s the maximum thickness a rolling machine can handle?

It depends on the machine. Some can handle plates up to 200mm thick, while others are designed for thinner materials. Always check the manufacturer’s guidelines.

Conclusion

Hydraulic plate bending machines are the backbone of modern metal fabrication. Whether you’re crafting a massive pipeline or a delicate aerospace component, these machines deliver unmatched precision and efficiency.

So, what’s next? If you’re ready to take your metal shaping game to the next level, it’s time to explore the world of steel plate roller machines. And hey, if you’ve got more questions, drop them in the comments below—we’d love to hear from you!