Bravo! YG-1 Automatic Stirrup Bending Machine exported to UAE. What is the automatic stirrup bending machine price? If you’re in the construction or rebar processing business in the UAE, and you want to buy the best automatic stirrup bending machine, YG Machinery is one of your best choices. Contact us to get the factory price.

In this article, we’ll break down everything you need to know about rebar stirrup benders in the UAE, from the factors that influence their price to the types of machines available, leading suppliers, and expert tips for making a smart purchase. Whether you’re looking to upgrade your equipment or purchase for the first time, this guide will help you make an informed decision and find the best value for your investment.

What is a Rebar Stirrup Bender?

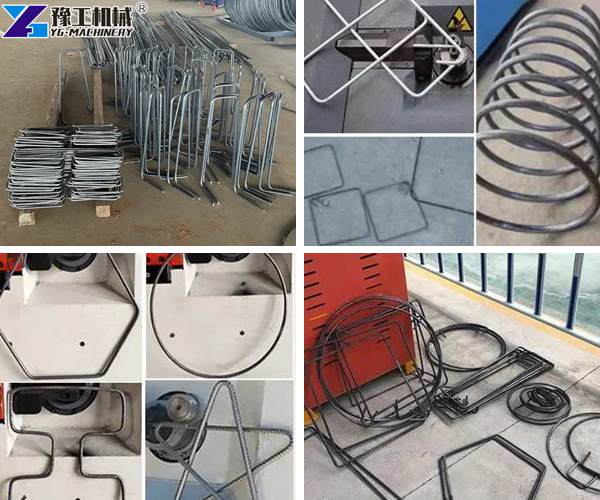

Rebar stirrup benders are specialized machines used in the construction industry to bend rebar (reinforcing steel bars) into precise shapes. These shapes, or stirrups, are then used in concrete reinforcement for beams, columns, and slabs. The primary function of a rebar stirrup bender is to ensure the rebar is bent with accuracy and speed, reducing manual labor and improving productivity.

Technical Parameters

| Model | YG-1 | YG-2 |

| Single wire | Round steel 4-10mm Deformed steel bar 4-8mm | Round steel 4-12mm Deformed steel bar 4-10mm |

| Double wire | Round steel 4-6mm Deformed steel bar 4-6mm | Round steel 4-8mm Deformed steel bar4-8mm |

| Max bending angle | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min |

| Maximum bending speed | 800°/sec | 800°/sec |

| Machine size | 2600*800*1700mm | 3280*1000*1700mm |

| Pieces Processed | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa |

| Total Power | 14kw | 20kw |

| Working temperature | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° |

| Average power | 4.5KW/h | 5KW/h |

| Total weight | 1150KG | 1350KG |

Key Functions and Features:

- Precision: The machine allows for accurate bends, crucial for maintaining the structural integrity of reinforced concrete.

- Speed: High-speed bending can significantly improve workflow in a busy rebar workshop or construction site.

- Automation: Many modern machines come with programmable controls to make complex bends quickly and with little human intervention.

Key Factors Affecting Rebar Stirrup Bender Prices in UAE

Rebar stirrup bender plays a vital role in shaping steel bars into stirrups, which are essential for reinforcing concrete structures. With a wide variety of options on the market, the automatic stirrup bending machine price in the UAE can vary significantly based on its features, specifications, and the brand.

Machine Specifications and Features

The primary factor driving the automatic stirrup bending machine price is its specifications and features. Machines with more advanced capabilities, such as higher bending capacity, automated controls, and multi-functional bending options, will generally cost more.

Brand Reputation and Manufacturer

The brand behind the rebar stirrup bender can significantly affect its price. Well-established manufacturers with a strong reputation in the industry, such as YG Machinery, tend to charge a premium for their products due to the assurance of quality, reliability, and durability.

Local UAE manufacturers or suppliers might offer lower-cost options, but they may not have the same technological features or longevity as international brands.

Local vs. International Brands

Technological Advancements and Automation

As technology continues to advance, rebar stirrup benders with cutting-edge features are becoming more common in the UAE market. Machines equipped with automation, digital displays, and even Artificial Intelligence (AI) for precise bending will command a higher price tag.

Why you should buy automatic stirrup bender?

In construction projects, the quality of the rebar stirrups directly impacts the durability and safety of the structure. The rebar stirrup bending machine streamlines the production of these critical components, ensuring that projects are completed on time and within budget. Furthermore, in rebar processing companies, the ability to quickly and efficiently produce stirrups reduces labor costs and enhances overall production efficiency.

Contact us to get the automatic stirrup bending machine price

As the construction industry in the UAE continues to grow, having the right equipment will not only boost your productivity but also position your company as a leader in efficiency. When purchasing a rebar stirrup bender, feel free to contact YG Machinery to get the best factory price.

Click the button below to get the automatic stirrup bending machine price.

FAQs:

How much does a rebar stirrup bender cost in the UAE?

Prices vary from AED 10,000 for basic models to AED 60,000 or more for advanced, automated models.

What’s the difference between manual and automatic rebar stirrup benders?

Manual models require operator input for each bend, while automatic machines are programmable for continuous operation, improving efficiency.

Can I buy a used rebar stirrup bender in the UAE?

Yes, used machines are available through various suppliers and can offer significant savings, but warranty and condition should be closely evaluated.

How can I maintain my rebar stirrup bender?

Regularly clean the machine, check for wear on moving parts, and ensure all electrical components are functioning to avoid downtime.

What factors influence the price of a rebar stirrup bender?

Key factors include the type of machine (manual vs. automatic), brand reputation, technological features, and the machine’s load capacity.