In the fast-paced world of garment and textile manufacturing, every second counts. Time saved translates to increased production, lower costs, and happier customers. But one area that has long been a bottleneck is the laborious and error-prone process of fabric spreading. So here is the automatic fabric spreading machine.

Fully automatic fabric spreading machine

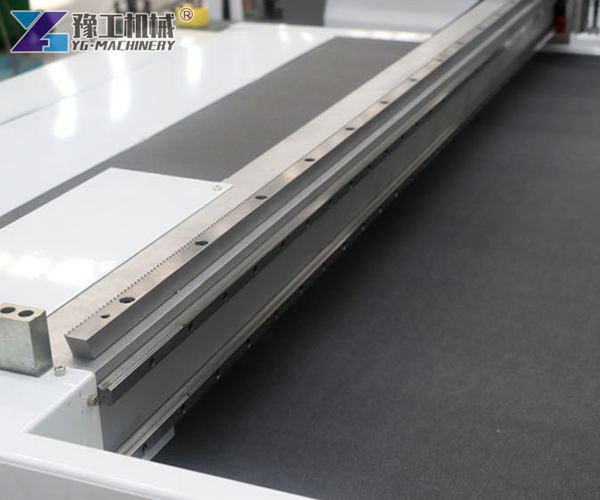

Spreading fabric for cutting and sewing garments, upholstery, and other textile products.

In this page, we will present all important informations about the fully automatic fabric spreading machine.

What is a fabric spreading machine?

A fully automatic spreading machine is a high-tech piece of equipment used in various industries, primarily in garment and textile manufacturing, to precisely lay out and spread large quantities of fabric or other materials.

Technical Parameters

| Machine type | K5-160 | K5-190 | K5-210 | K5-260 | K5-300 |

| Fabric width | 1600mm | 1900mm | 2100mm | 2600mm | 3000mm |

| Table width | 1830mm | 2130mm | 2330mm | 2830mm | 3230mm |

| Fabric weight | 100kg max | ||||

| Voltage/power | 220V/1.5KW | ||||

| Fabric diameter | 650mm max | ||||

| Spreading speed | 95m/min max | ||||

| Spreading height (K5) | Single pull height 230mm max Double pull height 200mm max | ||||

| Spreading height (K9) | Single pull height 280mm max Double pull height 230mm max | ||||

The Transformative Power of Fabric Spreading Machine

From Manual Drudgery to Automated Efficiency

Unmatched Speed and Accuracy

Imagine spreading hundreds of meters of fabric in minutes, with laser-guided precision. Fabric spreading machines do just that, eliminating human error and significantly boosting production speeds.

Reduced Waste, Increased Profit

Manual spreading often leads to fabric misalignments and cutting errors, resulting in wasted material. Automatic fabric spreading machine optimizes fabric usage by nesting patterns efficiently, minimizing waste and maximizing profits.

Enhanced Productivity and Scalability

Consistent, high-quality spreading paves the way for increased production capacity. Fabric spreading machines allow manufacturers to scale their operations efficiently, meeting fluctuating demands with ease.

Making Business Better for Everyone

Tired of slow, error-prone fabric spreading that eats into your profits? Say goodbye to manual labor and hello to the revolutionary world of automatic fabric spreading machines.

Types of fully automatic fabric spreading machine

In general, there are 3 different types of automatic fabric spreading machines available, each suited for specific applications:

- Laydown machines are used for spreading single layers of fabric.

- Multi-ply machines can spread multiple layers of fabric simultaneously, increasing productivity.

- Nesting machines optimize material usage by arranging the patterns on the fabric to minimize waste.

Applications

Fabric spreading machines aren’t just for garments. You can find them in diverse industries like:

- Composite materials: Layering carbon fiber and other composites for aerospace and automotive parts.

- Paper and cardboard: Spreading paper for packaging and other applications.

- Upholstery and furniture: Ensuring precise fabric placement for furniture pieces.

Investing in an automatic fabric spreading machine is an investment in your future. It’s a move towards efficiency, accuracy, and increased profitability. So, ditch the manual drudgery and embrace the transformative power of automated fabric spreading. Your business will thank you for it.

How to choose the right fabric spreading equipment for your needs?

Here are 4 factors you should consider when you are choosing the automatic fabric laying machine:

- Material type and thickness: Different machines are suited for different fabrics, from delicate silks to heavy canvas.

- Laydown or multi-ply: Do you need single-layer spreading or the ability to handle multiple layers?

- Nesting capabilities: Machines with nesting technology minimize fabric waste and maximize material utilization.

- Production volume and budget: Choose a machine that aligns with your production needs and budget constraints.

Still don’t know how to choose? Let our experts help you find the perfect solution.

Overall, fully automatic fabric spreading machine is valuable tools that can significantly improve efficiency, accuracy, and productivity in various industries. If you want to invest a fabric laying machine, please feel free to contact us.

FAQs

Can the parameters of the cloth spreading machine be adjusted at will?

A password will be set for the operation interface. Only managers and operators can set and adjust it. Non-staff members are not allowed to adjust it at will to avoid program confusion.

What are the methods of cloth-clothing machine?

The main methods of cloth spreading machine include: single pulling and double pulling. Double pulling must be equipped with front and rear pressing devices.

What kind of fabrics can the cloth pulling machine pull?

Knitting, woven, coated sports, home textile fabrics, non-woven fabrics, protective clothing, transparent fabrics, etc. For different fabrics, you need to purchase the corresponding machine model.