Do you want to invest a wate tire recycling machine? But you have not enough fund to buy a tire shredding machine? If you are in this situation, you can consider this solution – Tire cutting machine. Instead of purchashing a expensive double shaft shredder, add just some small tire strip cutting machine, you can also set up your cost-effective scrap car tyre recycling plant.

YG-850 Tire Sidewall Cutting Machine

This machine is used for remove two sidewalls from waste tyres.

Application areas: Block processing of waste tires, automobile tires, rubber tires, rubber finished products and other tire materials.

Technical Parameters

Power: 2.2kw

Processing diameter: 750-1200mm

Capacity: 2 t/h

Knife material: Cemented carbide

Knife life: Normal use of 300-500 tons tires

Size:1300×900×1480mm

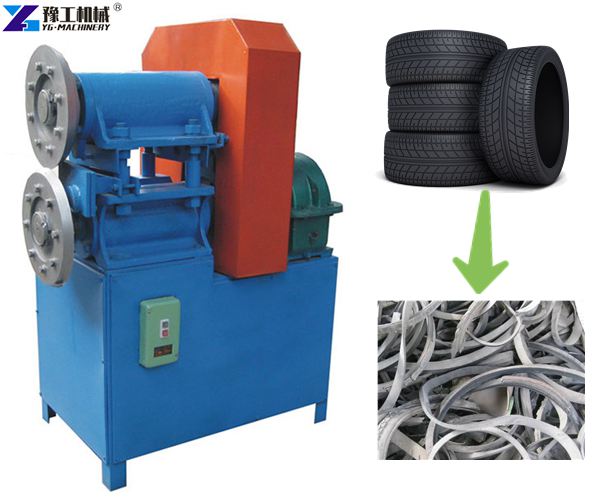

YG-380 Tire Strip Cutting Machine

The strip cutter can cut the steel wire tire with the sidewall removed by the circle cutter into strips, and the width of the strips is adjustable. The two circle disc cutters are made of special materials, which are hard and durable and can be repeatedly sharpened and used. They are suitable for steel wire tires not exceeding 1200.

Technical features

Power: 4kw

Processing diameter: 750-1200mm

Capacity: 1 t/h

Knife material: Cr12

Knife Diameter: Φ380mm

Knife life Normal: 6 months

Size: 1320×750×1580mm

YG-200 tyre block cutting machine

The tire block cutter is usd to cutting tires strips into rubber blocks(3-8cm). Through the waste tire cutting machine, waste tires can be effectively recycled and reused to reduce pollution to the environment.

Technical features

Power: 15kw

Processing diameter: 750-1200mm

Capacity: 1t/h

Knife Quantity: One fixed knife and two movable knives

Knife Material: YG8 cemented carbide

Knife life: Normal use of 300-600 tons tires

Process of processing waste tires to 3-5cm rubber blocks

In the process of processing waste tires from the whole tire to 3-5cm rubber blocks, tire bead cutting machine, tire strip cutting machine, tire block cutting machine and tire wire grinding machine are needed. There are four small models in total, which we usually call tire small four pieces or tire semi-automatic crushing small four pieces.

Bead cutting machine: This tire sidewall cutter is suitable for removing tire bead, which is a process of processing tires.

Strip cutting machine: This tire strip cutting machine is suitable for cutting tires of any specification below 1200mm and various large waste rubber into strips, which is the second process of processing tires.

Block cutting machine: This tyre block cutter is suitable for cutting strip rubber into 3-5cm rubber blocks, which is the third process of processing tires.

Waste Tire Steel Wire Separator: This fully automatic tire steel wire separator mainly separates the rubber and steel wire on various tire bead rings to obtain a complete steel wire ring. These are the four processes of processing tires.

Why you should choose this tire cutting machine?

Check below the advantages fo the waste tire cutting machine.

- Reasonable design, stable performance, long service life, low noise, no pollution, it is an ideal tire recycling equipment.

- The equipment occupies a small area and is easy to install.

- Low power consumption index.

- Corrosion-resistant, no wear, long service life.

- The equipment is reliable in operation and simple and convenient to maintain.

Tyre Cutting Machine Price

YG Machinery has more than 20 years of experience in the machine manufacturing. Our rubber shreadder machines have been exported to many countries, such as India, Chile, Brazil, the United States, Russia, etc. We provide the high quality machine at good price. We have our own after-sales services team.