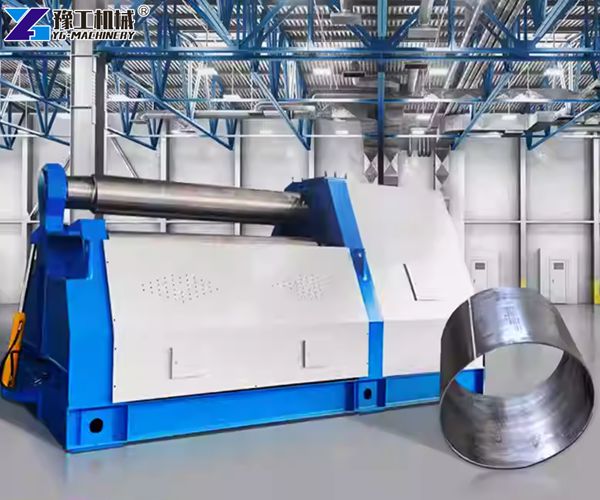

W12S-4×2500 steel plate rolling machine exported to Mexico.

Specifications of Steel Plate Rolling Machine

| Model | Working Length (mm) | Max. Thickness (mm) | Pre- Bending (mm) | Upper (Φmm) | Under (Φmm) | Side (Φmm) | Motor Power (km) | dimension(cm) |

| W12S-4×2000 | 2000 | 4 | 3 | 160 | 140 | 120 | 2.2 | 392x86x114 |

| W12S-4×2500 | 2500 | 4 | 3 | 190 | 170 | 150 | 3 | 402x125x138 |

| W12S-4×3200 | 3200 | 4 | 3 | 210 | 190 | 170 | 7.5 | 466x132x137 |

| W12S-4×4000 | 4000 | 4 | 3 | 270 | 250 | 210 | 5.5 | 600x143x152 |

| W12S-6×2000 | 2000 | 6 | 4 | 190 | 170 | 150 | 3 | 402x125x138 |

| W12S-6×2500 | 2500 | 6 | 4 | 210 | 190 | 170 | 7.5 | 466x132x137 |

| W12S-8×2000 | 2000 | 8 | 6 | 210 | 190 | 170 | 7.5 | 416x132x137 |

Working Case in Mexico

Meet Carlos Herrera, a seasoned metal fabricator from Monterrey, Mexico. For years, Carlos ran a small fabrication shop specializing in custom metal components for the booming construction and automotive industries in northern Mexico. But as demand grew, he faced a frustrating challenge—his outdated manual rolling methods couldn’t keep up with large orders for curved steel structures, pressure vessels, and cylindrical metal parts.

One day, while searching for a high-performance steel plate bending machine, he stumbled upon YG Machinery. After an in-depth consultation, he decided to invest in a hydraulic four-roll plate rolling machine—a game-changer for his business. Within weeks of integrating the machine into his production line, Carlos saw a 40% increase in efficiency, allowing him to take on larger, more complex projects.

With YG Machinery’s precision rolling technology, Carlos secured a contract to supply curved steel panels for a major infrastructure project in Mexico City. Now, he’s expanding his workshop, proving that the right machine can transform a small business into an industry leader.