Bravo! YG-2 Automatic Rebar Stirrup Bender Machine exported to Colombia.

A Colombian Business Owner’s Journey to Finding the Right Automatic Rebar Stirrup Bender

Meet Juan Rodríguez, a rebar processing entrepreneur in Bogotá. For years, his company struggled with manual rebar bending, which was slow, inconsistent, and labor-intensive. His workers often spent hours adjusting measurements, leading to material waste and delays in delivery to construction sites.

One day, Juan watched a YouTube video of an automatic rebar stirrup bender, smoothly bending rebar with precision at 10 times the speed of manual labor. That’s when he realized—it was time to upgrade.

But with so many options in the market, how could he choose the right machine for his growing business? He needed:

✔ A machine that handles different wire diameters (since his projects required varying rebar sizes).

✔ Something affordable yet durable, considering import costs to Colombia.

✔ A supplier who offered good after-sales support (because technical issues would cost him money).

After weeks of research, Juan finally found the perfect machine—a YG-2—and imported it through a trusted supplier YG Machinery. The results?

✅ Production doubled in the first month.

✅ Labor costs dropped by 40%.

✅ More consistent stirrups meant less material waste and higher profits.

If you’re in Colombia and facing the same struggles as Juan, this guide will help you make the right investment decision for your rebar business. Let’s dive into everything you need to know about automatic stirrup benders.

Technical Parameters of automatic stirrup bender

| Model | YG-1 | YG-2 |

| Single wire | Round steel 4-10mm Deformed steel bar 4-8mm | Round steel 4-12mm Deformed steel bar 4-10mm |

| Double wire | Round steel 4-6mm Deformed steel bar 4-6mm | Round steel 4-8mm Deformed steel bar4-8mm |

| Max bending angle | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min |

| Maximum bending speed | 800°/sec | 800°/sec |

| Machine size | 2600*800*1700mm | 3280*1000*1700mm |

| Pieces Processed | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa |

| Total Power | 14kw | 20kw |

| Working temperature | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° |

| Average power | 4.5KW/h | 5KW/h |

| Total weight | 1150KG | 1350KG |

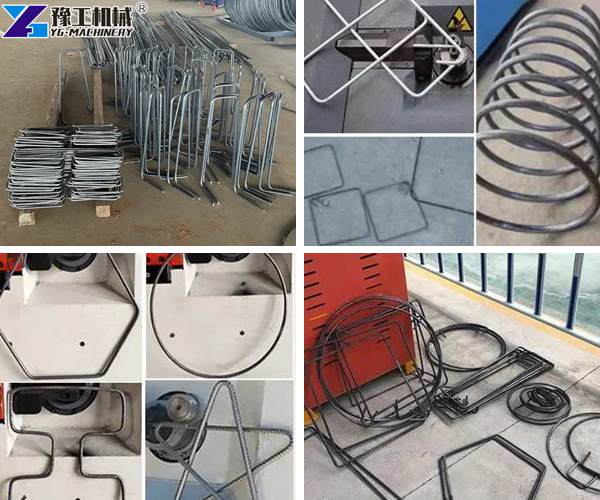

What Are the Typical Applications for Stirrups Produced by These Machines?

Rebar stirrups are essential in reinforcing concrete structures. The precision and speed of an automatic stirrup bender make it perfect for applications like:

???? Building Foundations – Ensuring structural integrity for skyscrapers and bridges. ???? Columns and Beams – Providing crucial reinforcement in vertical and horizontal construction. ???? Precast Concrete Products – Used in prefabricated panels, walls, and tunnel segments. ???? Road and Infrastructure Projects – Strengthening bridges, tunnels, and retaining walls.

Final Thoughts: Is an Automatic Stirrup Bender Worth It?

If you’re serious about speed, precision, and cost savings, an automatic stirrup bender is a no-brainer. It’s an investment that pays for itself in labor reduction, material savings, and project efficiency.

So, are you ready to upgrade your rebar processing game? Check out leading manufacturers and find the best stirrup bender for your needs today!