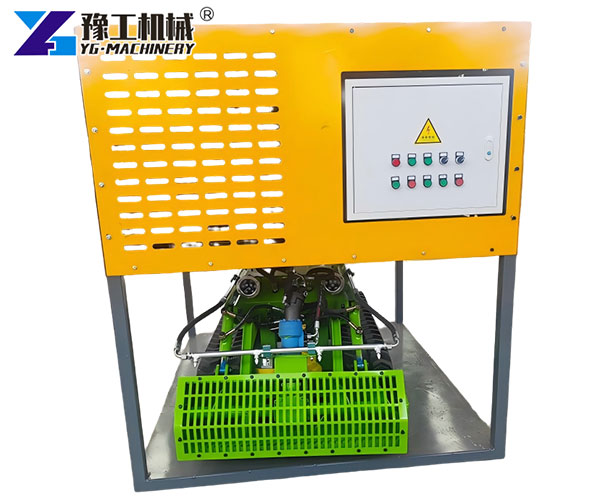

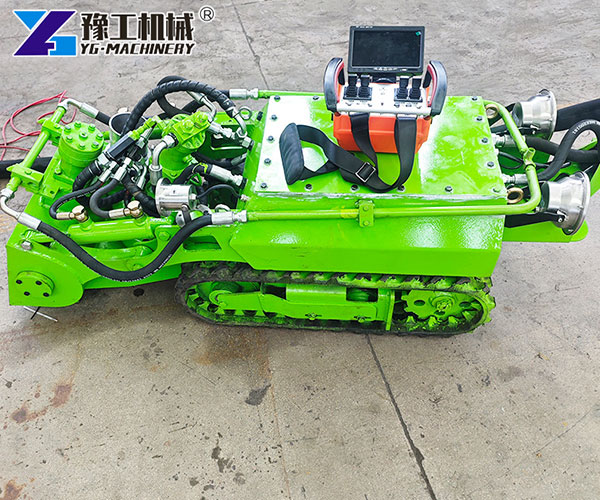

A Sludge Cleaning Robot is an automated machine that cleans sludge from tanks, ponds, and sedimentation basins. It is remote-controlled or semi-automatic. The robot moves on crawlers or wheels, breaks compacted sludge, and pumps the slurry out to an external tank.

This device helps plants remove sludge without sending workers into confined or dangerous spaces. Automation is rising because it is safer, faster, and more reliable than manual cleaning.

Why Customers Need A Sludge Removal Robot

Many plants face the same problems when they clean sludge:

- Tanks, clarifiers, and reaction pools fill with thick sludge.

- Manual cleaning is slow and costs a lot in labor.

- Stopping the plant to clean means lost production time.

- Confined spaces create serious safety risks for workers.

- Traditional pumps and wash systems cannot reach corners and deep spots.

A sludge removal robot solves these issues by working inside the tank and reaching places that people or simple pumps cannot.

Key Benefits Of A Sludge Cleaning Robot

The Sludge Cleaning Robot gives users clear benefits:

- No worker entry into confined or dangerous spaces.

- Stable operation for long continuous shifts.

- Works well in high-viscosity and heavy accumulation.

- Cuts shutdown time and lowers operating cost.

- Enables fine cleaning and sludge recovery for reuse.

These advantages make the robot a smart long-term investment for plants and factories.

Key Features Of Industrial Sludge Cleaning Machine

Our industrial sludge cleaning machine includes the following features:

- Powerful propulsion system for rough sludge and slope work.

- HD camera and live video feed for safe remote control.

- High-efficiency sludge pump and suction unit.

- Corrosion-resistant structure for harsh chemical environments.

- Long cable or optional tether with safe control options.

These features help operators clean faster and with better control.

Tank Sludge Cleaning Robot Working Scenarios

The tank sludge cleaning robot fits many sites:

- Wastewater treatment plant clarifiers and sedimentation tanks.

- Chemical storage tanks and reaction vessels.

- Food factory and paper mill sludge pits.

- Power plant cooling tower basins.

- Any place where the shutdown cost is high and safe cleaning is needed.

The robot can work while the tank stays partly in service in many cases.

How the Wastewater Sludge Cleaning Robot Works

The wastewater sludge cleaning robot follows a clear workflow:

- Lower the robot into the tank from the top.

- Use camera feed and controls to move to target areas.

- Cut or agitate compact sludge with the front tool.

- Suction pump sends sludge to an external tank or tanker.

- Repeat until the cleaning depth is reached.

This simple cycle reduces human risk and speeds up cleaning tasks.

Return On Investment

Consider these economic benefits:

- Lower labor costs because fewer people enter the tanks.

- Less downtime leads to higher production uptime.

- Reduced rework from incomplete manual cleaning.

- Recoverable sludge can be reused or sold.

- Low maintenance due to modular parts and easy service.

Most customers see payback in months to a few years, depending on cleaning frequency.

FAQ about Sludge Cleaning Robot

Q: Is the robot safe in chemical tanks?

A: Yes, with corrosion-resistant options and proper seals.

Q: How deep can it clean?

A: Models vary; we offer small to large units for shallow to deep tanks.

Q: Do you provide training?

A: Yes. We provide online training, manuals, and videos.

YG Machinery After-Sales Service

YG offers full support:

- Online training and remote control assistance.

- Spare parts supply and scheduled maintenance.

- Export experience and case documentation for global projects.

- Fast technical response and video troubleshooting.

We help clients keep robots running with minimal downtime.

Why Choose Our Sludge Cleaning Robot

Choose our solution because:

- Core tech developed in-house with real field tests.

- Many successful cases in tanks, sewage plants, and factories.

- Full export and documentation support for global buyers.

- Fast response and project consulting to match your site needs.

Still don’t know how to choose? Let our experts help you find the perfect solution.