A Tank Cleaning Robot is now widely used in industries because it makes tank cleaning safer, faster, and more cost-effective. Traditional manual tank cleaning has high safety risks, slow speed, and heavy labor costs. Workers need to enter a toxic, dirty, and narrow space, which easily leads to accidents.

With a robot, the operator does not need to enter the tank. This non-entry tank cleaning solution greatly improves safety and reduces operation time. It is suitable for many tank types, including chemical tanks, oil tanks, food tanks, sludge tanks, and pharmaceutical tanks.

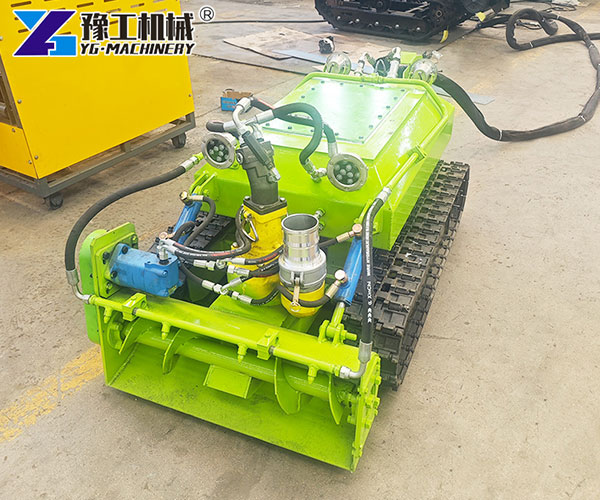

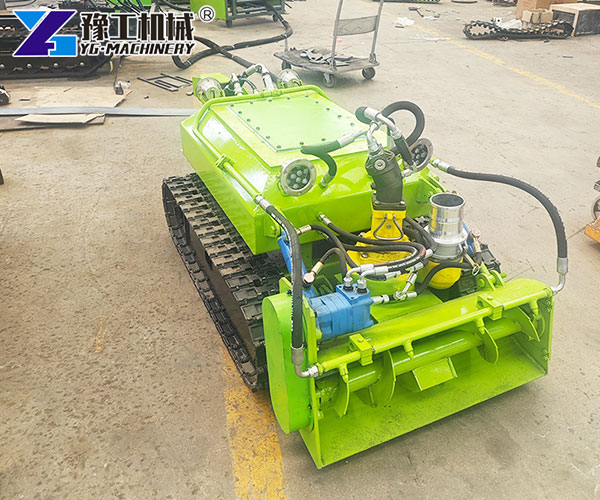

Structure Of The Tank Cleaning Robot

The machine is built with a strong industrial structure designed for long hours of cleaning work. The main parts include:

- Cleaning robot body

- Hydraulic pump unit

- Hydraulic hoses

- Wastewater suction pipe

- Remote control system

The high-pressure jet system breaks down sludge, sediment, and chemical waste inside the tank. The crawler-type walking system allows the robot to move slowly and steadily on slippery or sticky tank bottoms. Cameras, sensors, and liquid-level monitoring systems are available as optional modules to improve visibility and cleaning control.

Key Features of Industrial Tank Cleaning Machine

A Tank Cleaning Robot provides several important features for safe and efficient tank maintenance:

- No worker needs to enter the tank

- Handles oil sludge, sediment, and chemical residue

- HD video camera ensures a clear and clean view

- Crawler drive works well on wet or sticky surfaces

- Anti-corrosion body and a strong high-pressure pump

- The waste liquid recovery system keeps the tank cleaner

These features make the robot suitable for both small and large industrial tanks.

Match The Right Tank Cleaning Robot To Your Scenario

Choosing the right configuration depends on real working conditions. Important factors include:

- Tank size: capacity, diameter, height, entry size

- Tank type: oil tank, chemical tank, food tank

- Sludge or sediment thickness

- Work environment: toxic gas, explosive zone, narrow space

- Automation level: semi-auto, full-auto, remote operation

Matching these factors ensures effective and safe cleaning performance.

Typical Applications Across Industries

A Tank Cleaning Robot is used in many industrial fields:

- Petroleum & chemical storage tanks

- Food processing liquid tanks

- Pharmaceutical tank cleaning support

- Sewage plant sludge tanks

- Coating and paint sediment tanks

These industries need fast and safe cleaning without stopping production for too long.

Engineering Quality And Safety Assurance

Quality and safety are important for long-term operation. Key engineering features include:

- Anti-corrosion, high-temperature-resistant materials

- Industrial-grade motor and high-pressure pump

- Optional explosion-proof configuration

- Reliable control system

- Multi-layer safety system: emergency stop, liquid-level monitoring, pressure protection

These features make the robot durable even in harsh working environments.

Advantages of Non-Entry Tank Cleaning Solution

We offer strong support to help customers use the robot smoothly:

- OEM / ODM service

- Global shipping and technical support

- Supply of parts: high-pressure pump, nozzles, camera modules

- Remote debugging, video training, and onsite support

This ensures long-term performance and easy maintenance.

In addition to oil tank cleaning, we also provide Dredging Robot for Reservoir Clearing and an Underwater Cleaning Robot.

Still don’t know how to choose? Let our experts help you find the perfect solution.